Horizontal Roller Mill,Horomill for Sale

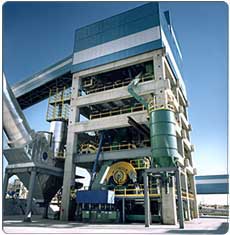

The horizontal roller mill (Horomill) consists of a horizontal cylinder supported on slideshoe bearings and driven through an open gear train. Terms used to describe the principles of operation of a Horomill include a bed material compression mill, a multi-compression mill, and a high-capacity mill.

The material passes into the mill at one end of the cylinder and, because of the centrifugal effect caused by operating the cylinder above the critical speed, is carried as a uniformly distributed layer of material on its inner surface. The finished product is collected in a dust filter, while the coarse particles are recycled to the mill. The grinding force is transmitted to the roller by hydraulic cylinders. Internal fittings are provided to control the material recirculation. It’s been reported that the grinding process based on multiple compressions gives the machine a high stability, and also the recirculating load can be adjusted to suit the quality target.

Compared to a ball mill, the Horomill operates with a larger grinding bed thickness and moderate pressures that lead to energysavings of 35% to 40% when used for cement grinding. In operation, the specific costs related to the liner and wear parts are higher than in an equivalent ball mill.

PRINTGET PRICEPrevious: A wise choice for limestone and coal grinding in the cement industry

Next: High Pressure Grinding Roll for Sale

Tags: Horizontal Roller MillHorizontal Roller Grinding MillHoromill

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)