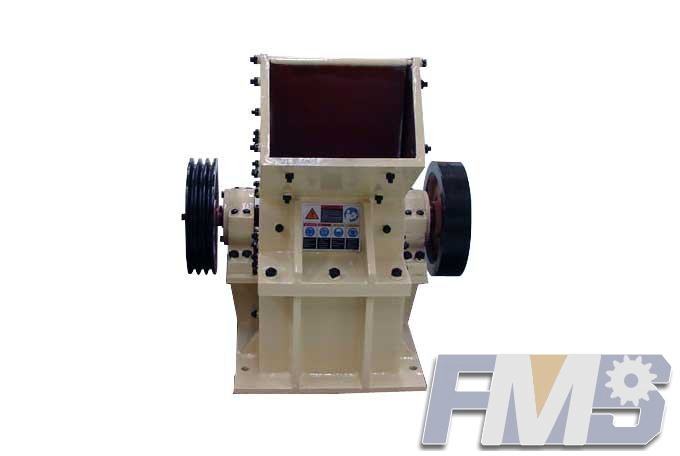

Impact Crusher for Secondary and Tertiary Crushing

The Impact Crusher family consists of two main types of impact crushers.

The conventional type has horizontal shaft configuration, known as PF Crusher. The other type consists of a centrifugal crusher with vertical shaft, generally known as VSI Crusher. The impact crusher operation is based on the principle of rapid transfer of impact energy to the rock material. The impact crusher produce cubic products, and they can offer high reduction ratios as long as the feed material is not too fine. This means that in certain cases it is possible to use a single impact crusher to carry out a task normally done in several crushing stages using compressing crushers (i.e., jaw, gyratory, and/or cone crushers). The impact crusher are mostly used for nonabrasive materials.

The two main types of impact crusher can be further subdivided, into various groups.

Conventional horizontal-shaft impact crushers are available in various sizes and models, from high-capacity primary crushers for large limestone quarries to specially designed machines for the crushing of materials such as slag.

There are two main categories of VSI crushers – machines with impact wear parts around the body and machines that use a layer of accumu- lated material. The i rst type is in many respects similar to the conventional the impact crusher with horizontal shaft and rotor. The second type became quite popular in the past decade and is known as the VSI5X crusher. The difference between a conventional mpact crusher and a VSI of the VSI5X type is that the latter of ers lower operating costs, but its reduction ratio is lower also. In a VSI5X crusher, the material undergoes an intense rock-on-rock crushing process. In the other crushers, most of the reduction is done by the impact of stone against metal.

Customers operating old, rebuilt, or expanded plants often have problems with the shape of the product. In these cases, the addition of a VSI5X crusher in the i nal crushing stage of ers a solution to product shape problems.

The same applies to many mobile crushing units. As the number of crushing stages is normally small with this type of plant, it is almost impossible to obtain a good product shape unless the rock is relatively soft and thus more suited for the production of cubic product. A centrifugal crusher in the final stage can help to solve the problem.

The plant’s capacity and the size of the feed material are the main factors in selection of a primary crusher. To ensure good performance of the primary plant and prevent production losses, it is necessary to have an adequate correlation between the size of the feed material and the dimensions of the crusher feed opening. This means that the maximum size of feed material should be in the range of 60 to 80% of the crusher intake opening’s size. Factors that may have an ef ect on the choice include the type of feeder used, material l ow to the crusher, and the availability of the necessary means (like breakers) to remove large-sized boulders in the event of bridging at the material intake opening. In cases where capacity requirements are very high, the natural choice is a primary gyratory crusher.

Tags: Secondary Impact CrusherTertiary Impact CrusherSecondary and Tertiary Crushing Machine

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)