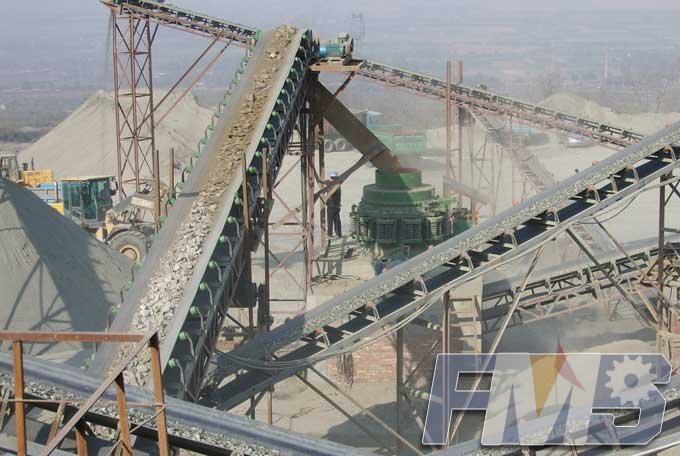

300-350 TPH Stone Crushing & Screening Plant

This production line is definitely one for large stones crushing plant with a capacity of 300-350 t / h.

For primary stage of crushing plant, either jaw crusher, or impact crusher can be selected. Impact crushers are performing well in high crushability soft rock, and low abrasiveness applications and jaw crushers are performing very well in hard rock, high abrasiveness applications. They can be also used for low abrasiveness rock, soft and hard.

In fine crushing applications there are more possibilities for crusher selection depending on the application. For high crushability, low abrasivenss, for example Limestone, there are rock- on-anvil VSI crusher and HSI crusher that would suit to the job. For good shape requirement, rock-on-rock VSI crusher is performing well in all kinds of applications regardless of the high abrasivenss. The maximum feed size is then limiting the use of rock-on-rock VSI crusher. The fine cone crushers are flexible what comes to feed maximum size, as there are different size of liners available.

Cone Crusher are performing very well with all kind of rock types. The only factors that are limiting the use of cones in fine crushing are fine aggregate- and moisture content. As a rule of thumb, minus 5 mm particles aren’t recommended to be fed into cone crusher, and max. recommended moisture content in the feed is 3%.

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)