Raw Grinding with Vertical Roller Mill

Cement raw material is principally a compound made of limestone and argillaceous rock, which undergoes mechanical and thermal treatment to create cement clinker. The geological formation, material composition and water content influence the grinding dryness and energy requirements.

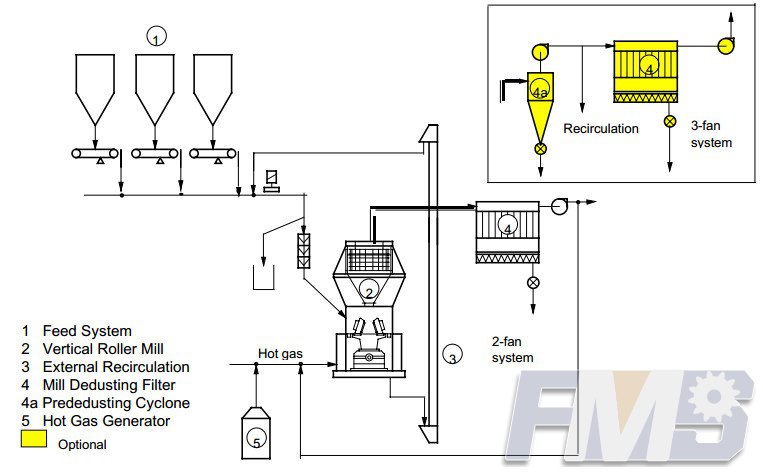

For dry and semi-dry kiln systems, the raw material components are ground and dried to a fine powder, making use mainly of the kiln exhaust gases and cooler exhaust air respectively. For relatively high moisture in raw materials and for start up procedures an auxiliary furnace may be needed to provide additional heat.

Vertical Roller Mill

The material to be ground is crushed between the rotating grinding track and the individually guided grinding rollers.

Grinding is carried out primarily through the application of compressive force. A small amount of shear force supports the displacement of crystalline layers in the raw material. This effect occurs through conical rollers whose axes are inclined at 15° compared to the horizontal grinding track. As already demonstrated through comparative studies in the 1930s, this permits ideal fine grinding and at the same time ensures minimum wear.

A higher specific grinding pressure is applied compared to coal grinding and a lower specific grinding pressure is applied compared to the fine grinding of clinker and granulated blast furnace slag.

Hot gases are added in the dry-grinding process to evaporate material moisture. Use is predominantly made of the exhaust gases from the rotary kilns, the heat exchanger or the cement clinker cooler. If none of these sources are available or the heat content of these exhaust gases is insufficient, Loesche’s own hot gas generators are deployed. In the classifier above the grinding chamber the ground product is separated from the grit which then falls back onto the grinding track for renewed grinding.

Tags: Vertical Roller Millcement grinding millsEquipment Grinding Cement Raw MaterialRaw Grinding Machine

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)