Hard Rock Process Plant

Figure below depicts the flowsheet for a plant producing various forms of dry (uncoated) roadstone including high PSV (+60) surface chippings. The production of surface chippings would probably require that a gritstone was being quarried. Many igneous rocks, such as granites and basalts, exhibit moderate values of PSV and are suitable for all other types of roadstone (see Chapters 10 & 11) and reference is made to their production. Limestones have a very low PSV but are used extensively in road construction below the wearing course. The operation of a quarry solely for the production of high PSV surface chippings cannot justified so it is likely that any gritstone will also be sold as dry stone, macadams and even concrete aggregate. Since any quarry is likely to contain beds of lower quality and weathered rocks it will also produce fill materials.

The quarried stone is dumped onto a grizzly feeder which removes scalpings and feeds the oversize to the primary double-toggle jaw crusher for breakage. The scalpings are re-screened at a finer size to increase the yield of clean stone.

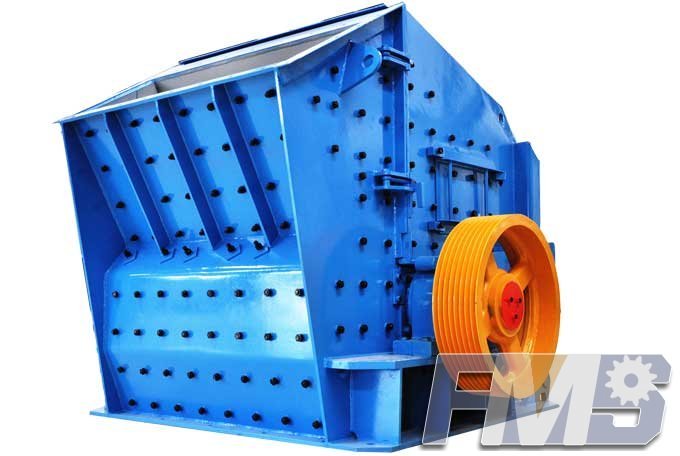

Where a soft limestone (containing little silica as flint or chert) is being processed the primary crusher may also be a jaw crusher, usually of the single-toggle type, although fixed blowbar impactors are common. Elsewhere in the flowsheet impactors will be used in place of cone crushers. Where the throughput of the plant exceeds 1000tph, especially for igneous rocks, the jaw crusher is replaced by a primary gyratory crusher. In this case, the dump trucks usually discharge directly into the crusher and scalping is carried out upon the primary crusher product.

The crushed rock is fed onto a stock-pile ahead of the main process plant from which it is reclaimed by a tunnel conveyor. This arrangement permits the plant to operate outside the hours of the quarry and during interruptions to quarry operations. A market may also exist for this 'crusher-run' material. Reclaimed stone is further crushed by a secondary cone crusher but a secondary gyratory might also be used. In order to increase plant capacity a primary screen can be installed ahead of the secondary crusher to remove material finer than the setting of the crusher which by-passes this stage of comminution. The material is now screened with oversize being recycled to the secondary crusher.

Commonly, the crusher product is divided into coarse and fine fractions prior to sizing as finished products. At this stage it is probable that this simple screening will generate saleable materials having relatively wide size distributions. Type 1 dry stone aggregate for road construction is a good example relevant to the UK which may constitute a substantial proportion of the quarry output. Provi- sion is made for recovery and stocking of this product.

Screening of the crushed aggregate into narrow size ranges employs multiple deck vibrating screens often mounted directly above the respective storage/outloading bins. However, screening of the secondary crusher product is unlikely to yield sized stone in the proportions demanded by the markets which are usually greater for the finer aggregates. Provision is made for recrushing the coarser fractions through a tertiary cone crusher. Indeed, the bin system can be designed so that once the bins containing coarser sizes are full they overflow automatically to feed the recrushing circuit. Fine aggregates may also be recrushed and recirculated to the fine screens. Machines suitable for this purpose, which may be encountered in various combinations, include fine cone crushers, vertical shaft impactors (illustrated) and gyratory disc crushers for the manufacture of sand. The impactor or cone crusher, operating with a low reduction ratio, may also be used at this stage to impart a cubical shape to the product intended for surface chippings.

Tags: Hard Rock CrusherHard Rock Process PlantRoadstone Crushing MachineRoadstone Crusher

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)