Recycling Concrete Plant

In many urban areas, limited available landfill space and traffic congestion, with its attendant air pollution, have become critical problems. Recycling concrete rubble is becoming an economically viable method of conserving landfill space and providing other environmental benefits.

Process for Recycling Concrete

There are two types of concrete recycling operations. One is the project where rubble from a runway, highway or building is recycled and reused in new construction. The other is the urban rubble disposal area where concrete from various sources is accumulated and recycled for sale to the general public.

Mobile Crushing Plant for Recycling Concrete

In project recycling, much greater control can be exercised in tailoring the end product. Knowing the quality and quantity of the existing concrete enables the production of a uniform material. Controlling the demolition process and coordinating it with the recycling process allows the demolished rubble to be sized for efficient crushing. Contamination of the rubble with dirt, trash and other objectionable material can be minimized with close supervision.

The urban disposal area provides a place to dispose of rubble close to its source of origin. The quality of the rubble varies substantially, and there is less control of contamination by trash and other objectionable material.

In either of these situations, the need to carefully segregate recyclable concrete rubble and other recyclable materials during the demolition process can not be over emphasized. Once rubble has been contaminated, additional cost is incurred, the end product quality may be compromised, or in extreme cases, it may not be possible to produce a usable product.

The recycling process involves crushing, removal of reinforcing steel and contaminates, screening and stockpiling the processed material. At the primary crusher, the rubble is reduced to about 4" maximum size to free the reinforcing steel which is removed by magnets and by hand. Objectionable material including wood, plastic, and other trash is picked by hand from the conveyors and screen. The material is sized byscreening with the oversized material going for further reduction to a secondary crusher then returning to the screen. After screening, the processed material is stockpiled where it will be loaded for shipment. Stockpile maintenance procedures are necessary to prevent segregation of multigraded materials like flexible base.

In urban areas, effective procedures for controlling dust and noise are critical. Dust can be effectively controlled with properly located water sprays and flooding. Noise can be mitigated by strategically located rubble and processed material stockpiles and standard noise control equipment like mufflers.

In project crushing, it is very important to carefully address logistical issues. Adequate space must be provided for rubble stockpiles, the processing plant, and processed material stockpiles. This space must be located to not interfere with site grading, building construction, underground utilities, or site access. The time between demolition and stockpiling rubble and the use of the processed material must be carefully coordinated with the construction schedule.

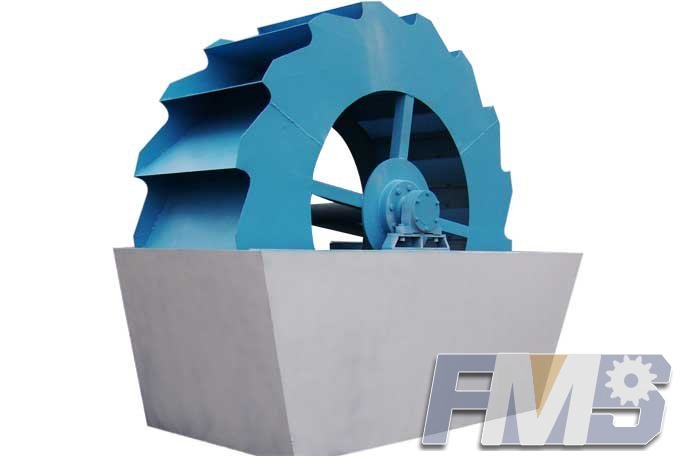

Concrete recycling Machine

Concrete aggregate collected from demolition sites is put through a crushing machine. Formats Construction Machinery have recently developed many new or modified existing equipment specifically for concrete demolition and recycling. These developments include Ô a wide range of breakers, crunchers, saws and crushing equipment. The manufacturers of primary crushing equipment have designed jaw and impact crushers specifically to handle flat material like pavement slabs and to reduce concrete rubble to the small size necessary to free the reinforcing.

Through our experience, we believe that the plants consisting of a jaw primary crusher with a cone, jaw, or impact secondary crusher are best for the urban recycling center. These plants are reliable and require a lower level of maintenance. However, these plants have a much higher capital cost and are not as readily portable as the closed cycle impact crushing plants. The impact crusher plants are very mobile and well suited for short-term projects.

Tags: Plant for Crushing ConcreteRecycling Concrete PlantConcrete Crushing EquipmentConcrete Recycling MachineConcrete Crusher

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)