Pebble Crusher

Jaw crusher PE as primary crushers, Cone Crusher Series HP as secondary crushers, Impact Crusher VSI as tertiary Crusher

A pebble is a clast of rock with a particle size of 2 to 64 millimetres based on the Krumbein phi scale of sedimentology. Pebbles are generally considered to be larger than granules (2 to 4 millimetres diameter) and smaller than cobbles (64 to 256 millimetres diameter). A rock made predominantly of pebbles is termed a conglomerate. Pebble tools are among the earliest known man-made artifacts, dating from the Palaeolithic period of human history.

Grinding process

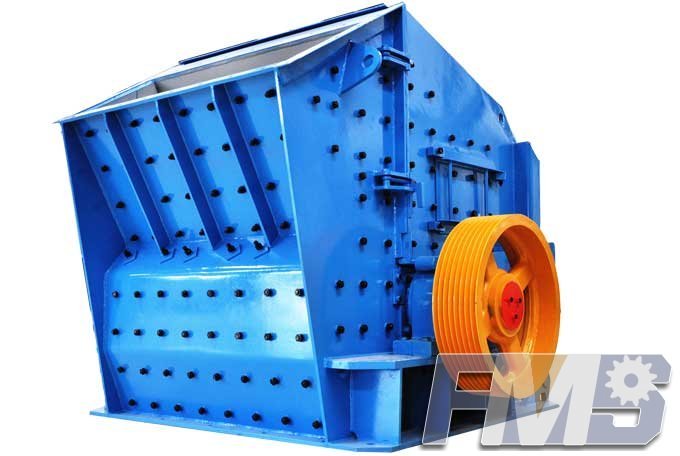

The River Pebble is so hard, but it has high silica content. Therefore, the process of crushing Pebble must have an affordable, considering the crushing cost of investment projects at the same time. Based on these factors, we recommend jaw crusher PE + cone crusher HP+ Impact Crusher VSI for crushing Pebble. The figure 1. is a pebble crushing plant site which is Provided by one of our Customer.

Figure 1. Pebble Crushing Plant for Aggregate and sand

Although the three-stage crushing inevitably lead to higher costs of investment projects, but it is suitable for long-term operation and will greatly reduce production costs.

Single Crusher for Recommended Pebble - Cone Crusher HP

If your production line need to replace a single crushing equipment, Cone Crusher HP is Recommended. Formats is using significant resources to research compressive crushing in our own test crushing plant and studying customer operations in different kinds of application all around the world. The conclusions of this research work are found in solutions utilized with HP cone crushers.

GP cone crushers can be easily adjusted to dif- ferent types of production requirements with change of cavities, eccentric strokes, counter shaft speeds and dif erent control methods. Metso Minerals customer service specialist have the know how to recommend optimum parameters to maximize production of desired end products meeting required quality levels.

HP cone crushers can be easily adjusted to different types of production requirements with change of cavities, eccentric strokes, counter shaft speeds and different control methods. Formats customer service specialist have the know how to recommend optimum parameters to maximize production of desired end products meeting required quality levels.

Tags: Crushing Machine for River PebblePebble CrusherRiver Stone Crusher

If you have any questions, please do not hesitate to contact us. Our online customer service to provide you with 7x24 hours of service.

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)