Multistage Crushing and Ball Milling with HPGR

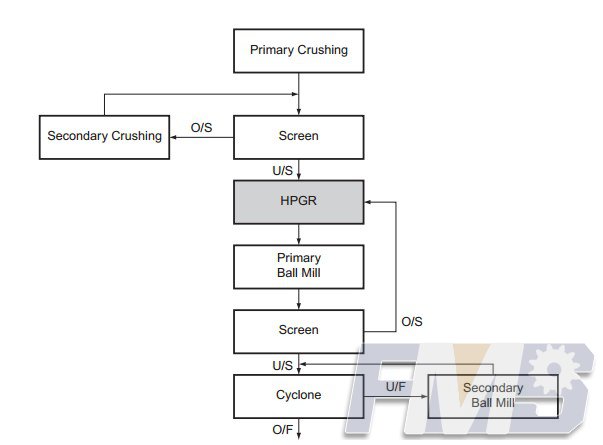

In this circuit, the HPGR is used in the tertiary crushing stage immediately ahead of the ball mills. This can be applied in new projects or as a retrofit to increase crushing capacity. However, for hard rock, it is important that the secondary crushing stage be operated in closed circuit to control HPGR feed top size, and this must be borne in mind when considering this circuit as a retrofit.

Three-stage crushing, closed-circuit

Depending on whether deagglomeration is indicated, the HPGR product screens may be operated dry (no deagglomeration required) or wet (mild deagglomeration). In the latter case, the dilute screen undersize slurry must be delivered to the mill sump rather than mill feed. Where intensive deagglomeration is required, the entire HPGR product is delivered to the mill, the mill discharge screened, and the screen oversize returned to the HPGR. In this case, it may be preferable to adopt a two-stage milling circuit, with the primary mill designed to minimise pebble generation, so minimising the return of moist material to the HPGR.

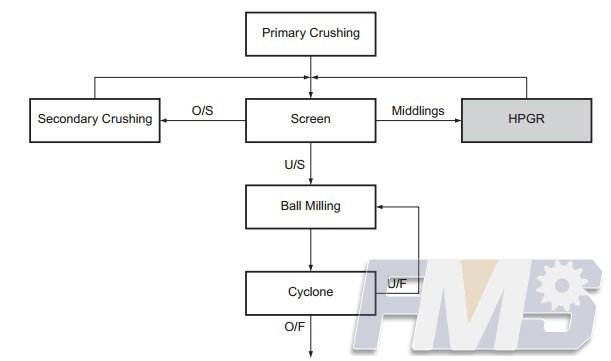

Three-stage crushing, open-circuit

This is inherently less efficient than delivering a controlled feed top size to the milling circuit, and it might be more efficient to use a dry deagglomerator on the HPGR product, such as a hammer mill or vertical impactor, followed by conventional dry screening.

Tagged: Multistage Crushing CircuitMultistage CrushingBall Milling

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)