Crushing Circuit for Production of Manufactured Sand

The quality of manufactured sand can range from a waste dust to a high quality, fit for purpose, fine aggregate. Most markets have a typical circuit arrangement that reflects the practice and requirements of the local concrete industry. To understand the use of manufactured sand, there needs to be an appreciation of the crushing and screening methods employed. Circuit arrangement is focussed on producing high quality shaped aggregates from the coarsest aggregates down to high quality manufactured sand. These high quality aggregates give the best performance in concrete.

Primary & Secondary Crushing

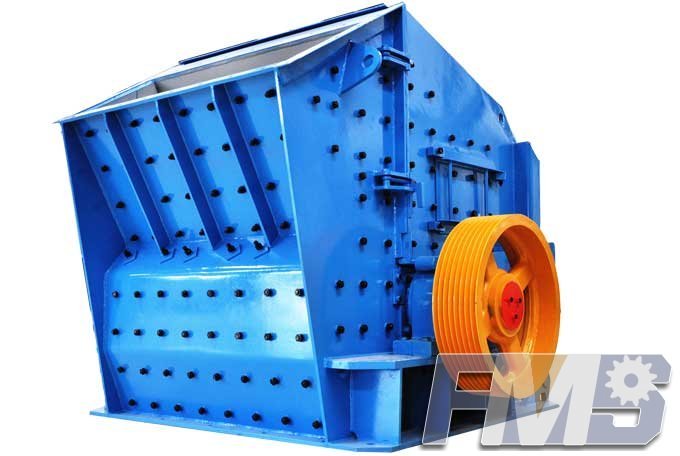

Compression crushers are employed in primary and secondary applications in nearly all crushing plants. Typically the primary is a jaw crusher receiving a plus 100mm (4") pit run material. Of the minus 100mm material either the minus 40mm or minus 65mm material is scalped depending on market requirements and quality of the pit run. The secondary, generally a cone crusher, processes the jaw product and material not scalped. The exception is low abrasive materials such as limestone where Horizontal Impact Crushers are preferred for their higher reduction ratios and improved particle shape. The main function of these crushers is reduction of the pit run material to a manageable particle size for the final phase crusher.

Tertiary Crushing

In the concrete aggregate market, VSI Crushers are applied in 100% of applications. The concrete industry has realised for many years that this type of crushing produces manufactured aggregates of the best quality. Crusher application is to produce proportionally, large amounts of manufactured sand and to shape all final products. Of the impact crushers employed, VSI5X rock-on-rock Vertical Shaft Impactors are installed at approximately 90% of all sites.

The final phase crusher is mostly installed in a post screen closed circuit arrangement. The top feed size to the circuit is a minus 40-50mm feed produced by the preceding crushers. This allows all crushed material to be processed into high quality coarse and fine aggregates, reducing the amount of waste fines created. In some countries the production of waste fines is an environmental problem which still requires a viable solution. By feeding the closed circuit a minus 40-50mm feed material and producing minus 22mm products, there is a percentage of the crusher throughput that is the result of re- circulating load. Practice has indicated this is of benefit for both the quarry and the concrete plant. It has been found that the re-circulating load improves the shape qualities of both the coarse and fine aggregate. For the quarry the benefit is to improve the requirements of the concrete plant, matching production with demand. The post screen circuit results in the production of amounts of 20-8mm product, which approximates to market demand.

Most concrete aggregate mixtures contain between 40-60% of minus 5mm with the balance being a graded coarse aggregate. Aggregate proportioning is dependent on the properties the concrete should have and its final use. The percentages of final products that a quarry produces should be matched as closely as possible to local market demand.

Tags: Manufactured Sand CrusherManufactured Sand Crushing PlantCrushing Circuit for Sand

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)