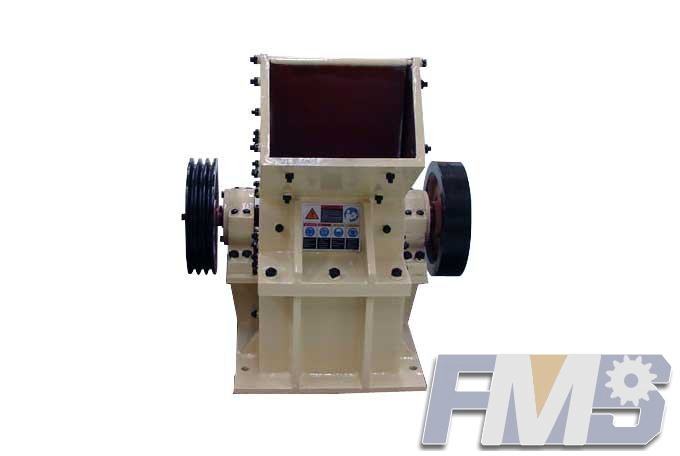

Jaw Crusher or Jaw Breaker

Due to their simple design and easy maintainability jaw crushers are widely used as primary size reduction equipments in mechanical and mining industries. As jaw crushers break minerals & ores of high strength and the economy of many industries depends on its performance; it is essential to improve the efficiency of the present design. The kinematic analysis of single toggle jaw crusher shows that the forces on the moving jaw plate at different crank angle are different and hence power generated varies with crank angle. One way to increase the efficiency is to store the energy in a flywheel when the supply is more than the rate of consumption and to utilize the same when the supply falls down. Hence efforts are made to design a flywheel to minimize the wastage of power and to improvise the performance parameters of single toggle jaw crusher.

Jaw plate wear has considerable affect on the life of jaw Crusher which is caused by the slipping motion between the fed material and the jaws. This wear is predominantly serious in the fixed plate and hence the liners of the fixed jaw should be properly chosen. In addition to this the toggle bar which acts as a safety lever has to be precisely designed. The design aspects of flywheel, spring of tension bar and toggle bar are discussed in this paper.

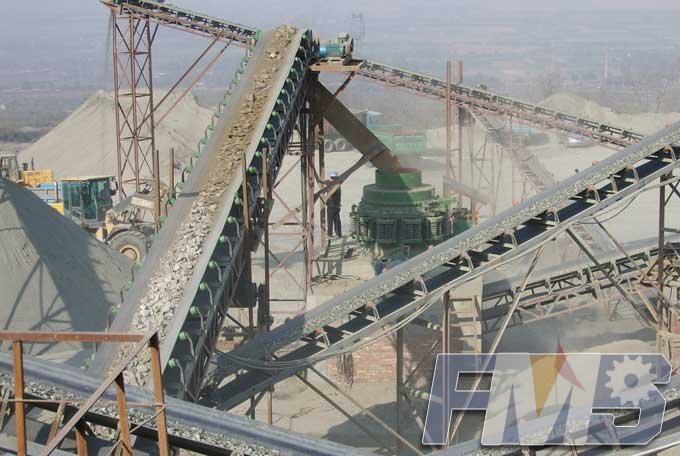

Crushing is the process of reducing the size of solid particles into definite smaller sizes. Jaw crushers are major size reduction machines used in mechanical, metallurgical and allied industries. The crusher crushes the feed by some moving units against a stationary unit or against another moving unit by the applied pressure, impact, and shearing or combine action on them. They are available in various sizes and capacities ranging from 5 ton/hr to 1500 ton/hr. They are classified based on different factors like product size and mechanism used. Based on the mechanism used crushers are of three types namely Cone crusher, Jaw crusher and Impact crusher.

Fracture occurs in the feed material when the strain developed in it due to sufficiently applied impact forces, pressure or shearing effect exceeds the elastic limit .Generally crushers are very rugged, massive and heavy in design. The contact surfaces are equipped with replaceable liners made from high tensile manganese or other alloy steel sheet having either flat or corrugated surfaces. Shearing pins or nest in heavy coiled springs are provided in the crusher to guard against shock and over load.

Tagged: Jaw CrusherJaw Breaker

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)