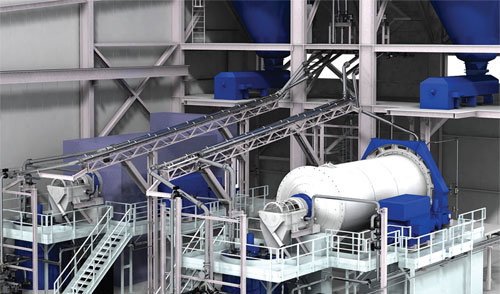

Cement Grinding Unit

Fineness and particle size distribution of the finished product have a strong influence on the cement quality. In modern grinding installations, fineness is mainly determined by the adjustment of separators as part of the mill system the oversize particles being returned from the separator to the mill inlet. Grinding systems with dynamic air (“high-efficiency”) separators offer the most flexible solution for plants producing a variety of cement types.

vertical roller mills

The working principle of vertical roller mills refers to the action of 2 to 4 “rollers” rotating on a horizontal grinding table or grinding bowl. Vertical roller mills can handle higher moisture contents in the mill feed and are therefore well suited for blended cements with higher rates of (moist) mineral additions or for separate grinding of mineral additions. Vertical mills can also be used for pregrinding in combination with a tube mill.

High pressure roller presses

High pressure roller presses so far exhibit the lowest energy consumption for the grinding process. However, they still need a comparatively high degree of maintenance, and the particle size distribution of the finished product has to be optimised. Roller presses are mainly used in combination with tube mills, either as a pregrinding unit or in a two-stage grinding process.

horizontal roller mill

A more recent development in cement grinding is the horizontal roller mill. It consists of a rotating horizontal shell and a horizontal roller inside which can be pressed hydraulically onto the shell. The mill feed passes several times between the roller and the shell along the mill due to centrifugal forces and fixed material transfer devices. Only few installations are in operation so far.

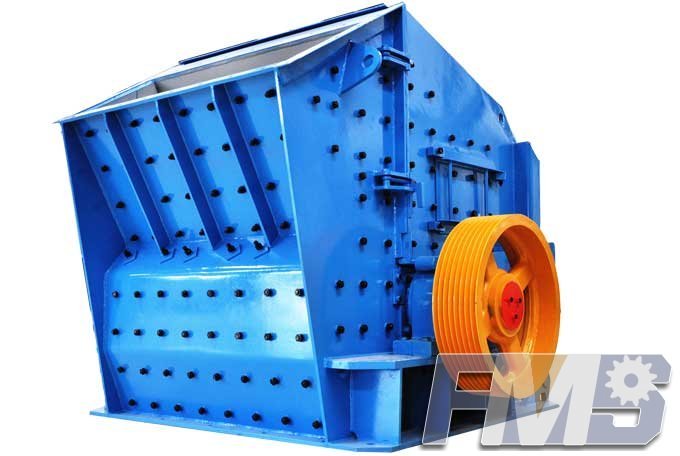

Ball Mills

Conventional tube (ball) mills with open circuit (without separator) are mainly used when producing only one type of cement. Closed circuit tube mills with a separator are more flexible, but – as with open circuit mills – are limited with regard to the moisture content of the mill feed. The consumption of electrical energy in tube mills is generally high compared to the other mill types.

Tagged: Cement Grinding EquipmentCement Mills ManufacturerCement Grinding Unit

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)