Equipments for Stone Processing

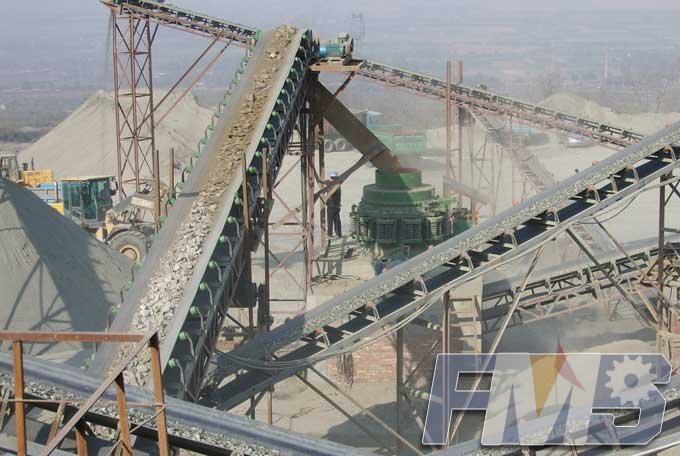

Stone processing activities include conveying, screening, secondary and tertiary crushing, and sizing. Screening is the single most important part of the processing cycle of crushed stone particles. A wide variety of screen types exist, and their selection is a function of the material processed and the final product required. Inclined vibratory screens are most commonly used in stationary installations, while horizontal screens are used extensively in portable plants. Large sizes of crushed stone, grizzly bars, rod decks, and heavy punched steel or plastic plates are used for screening. Woven wire, welded wire cloth, rubber, or plastic screens are used for smaller sizes. Stone is left by processing the crushed material across sizing screens where it is saturated with water, in order to remove unwanted material. Here is a video:

Need any information, please contact us.

Tagged: Stone Processing MachineStone Processing EuipmentsRock Crushing Machines

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)