High Pressure Grinding Roll for Sale

The high-pressure grinding rolls (HPGRs) have been offered as a comminution technology with claims of improved performance when compared to conventional grinding technology. In particular, it has been claimed that the HPRG has a lower specific energy consumption.

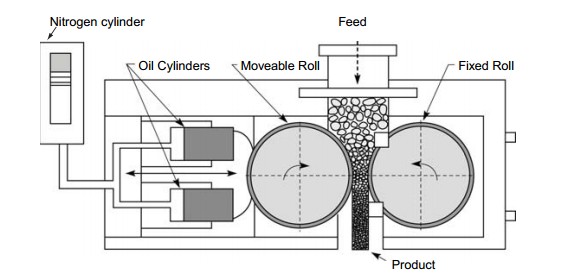

The material to be ground in an HPGR is compressed in a gap between two counterrotating grinding rolls with circumferential speed of 1 to 1.8 m/sec. The product from the HPGR is a compacted cake that contains fine particles and coarser particles with a large number of incipient cracks and weak points that greatly reduce the energy expenditure during further comminution.

The principle of operation of HPGRs

An HPGR can be used at different stages in the cement grinding process: precrushed, finish grinding, hybrid grinding, and semifinish grinding. When an HPGR has been used in the precrushed stage, 20% reductions in overall energy consumption have been achieved Hybrid grinding involves splitting the coarse fraction from the air classifier to the HPRGs and ball mill, respectively. In the semifinish grinding application, the HPRG is operated in closed circuit with the air classifier, and the fines from the separator are finally ground in a tube mill circuit. In the finish-grinding application, the HPRGs operate with an air classifier in closed circuit. Using this finish-grinding configuration, the potential energy savings can be as high as 50%, but the water requirements in the subsequent mortar production process are significantly higher due to the narrow size distribution produced.

PRINTGET PRICEPrevious: Horizontal Roller Mill,Horomill for Sale

Next: Grinding Mill Liner for Sale

Tags: HPGR CrusherHigh Pressure Grinding RollHPGRs for Grinding CementComminution Machine

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)