The Principle of High-Pressure Grinding Roll

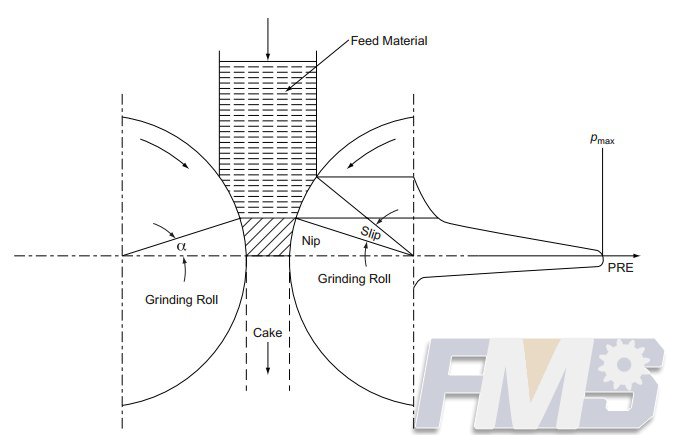

An HPGR consists of two counterrotating rolls, one of which is in a fixed location while the other one, a moving roll, is supported off hydraulic cylinders acting against a hydropneumatic spring that allows horizontal movement of the moving roll. The material to be ground is fed into the gap between the rolls. A small feed hopper, which always contains material, is installed above the rolls. The surfaces of the rotating rolls grip the material and pull it into and through the roll gap. For a certain arc length the material will slip on the roll surfaces until it reaches a point where the circumferential velocity and the material velocity are equal. This is called the nip zone.

High-pressure grinding—material slip and nip between the rolls

Because the horizontal distance between two locations on the roll surfaces decreases, the material is exposed to an increasing pressure. As it moves down, it reaches the maximum pressure approximately in the narrowest gap at the rolls’ centerlines. This pressure is so high that the material particles fracture. The majority of the feed particles are smaller than the narrowest gap. The maximum pressure pmaxis therefore exerted on a material bed rather than on single particles. This effect is called interparticle or packed-bed comminution. Not every particle that fractures need come into contact with the roll surfaces.

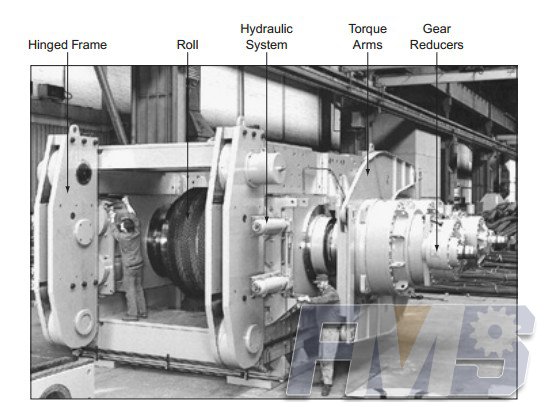

HPGR assembly at the workshop

Figure above views an HPGR from the side where the hydraulic system is located. The two grinding rolls are suspended with self-aligning roller bearings in bearing blocks, which are mounted in the machine frame. Each roll has its own drive train with planetary gear reducers. Torque arms are provided to neutralize the countertorques generated by the drives. This particular machine design features a hinged frame that swings open for easy roll exchange.

The energy density in the nip zone is quite high, about 400 times compared to a ball mill. Correspondingly high are the loads and stresses on the rolls, especially on the roll surfaces. The roll surfaces are of particular importance not only from the wear aspect but also for their capability to draw in the material.

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)