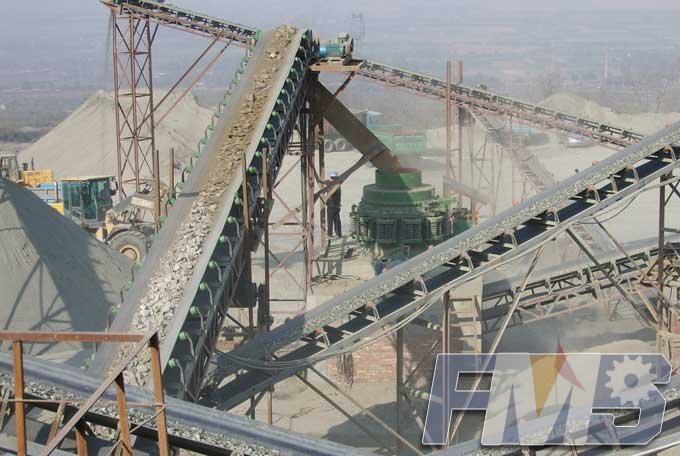

Stone Crusher in Mexico

If you speak Spanish, please visit http://trituradorasroca.com/Caso-en-la-Region/Trituradora-en-M%C3%A9xico.html

Mexico is located in North America, the northern border with the United States. We offer solutions and equipments for processing rocks and minerals in Mexico. For detail information, please contact our online customer service.

Formats is a developer of crushing solutions. Formats´s decades of experience in the design and manufacture of crushers has created a quantum increase in productivity, coupled with cost-effective operation and ease of maintenance.

Impact Crusher for Sale in Mexico

Impact crusher comprise a lined chamber within which revolves a rotor on a horizontal axis. The rotor is fitted either with swing hammers located by pins or blow-bars of alloy steel located by mechanical or hydraulic clamps. The hammers or blow bars impart impact to the rock resulting in comminution that is energy efficient and a typically cubical product shape. Impact with the rotor, the chamber liners (breaker plates) and interparticulate collision all contribute to comminution. Reduction ratios of 20:1 are achievable in a single stage and even 40:1 for double rotor impact crusher. The impactor thus offers several potential advantages of high reduction ratio, low capital and operating cost, ease of installation and low head room requirement and good product shape. Product size can be varied within limits by changing rotor speed and the clearances between rotor and liners.

The major limitation to the application of impactots is abrasive wear. Abrasive wear necessitates the costly replacement of hammers or blow-bars but, more importantly, results in loss of operating time, and low availability. Therefore, impact crusher tend to be restricted to crushing of non-abrasive rocks e.g. non-siliceous limestones and dolomites and to nonaggregate minerals e.g. coal, gypsum, salt. It has been stated that impact crusher are not suitable for rocks containing more than 5% free silica. Swing-hammer type impact crusher are generally applied to the production of the finer sizes of aggregate but impact becomes ineffective at a particle size less than about 3 mm.

The recent developments have mainly concerned the fixed blow-bar type which is now available as a primary crusher that can reduce very large lumps by a combination of impact and 'nibbling' actions. The use of a few large blow-bars forged from special alloys in place of many hammers and the design of the crushing chamber to permit very rapid access for maintenance, e.g. hydraulically actuated mechanisms for opening the casing and clamping wearing items, has overcome to some extent the principal disadvantage of impact crusher. They are now applied to the crushing of mineral ores, slags and siliceous limestones. Abrasive gritstones, quartzites and even basalt may also be crushed at the final stage by impact when the value of the cubical shape produced justifies the cost, e.g. surface chippings for roads or decoration.

Jaw Crusher for Sale in Mexico

The proven PE Series jaw crushers are suitable for any demanding crushing application. The latest model, PEX250×1200 jaw crusher, is designed to be a perfect fit for semi-mobile and mobile plants. The development of the PE series jaw crushers is based on reliability, productivity and safety. The crusher offer maximized reliability for the greatest availability over the product life cycle.

Cone Crusher for Sale in Mexico

Formats HP series cone crusher outperform the competition with rugged components and superior crushing ability designed into every machine. The HP Series cone crushers deliver up to twice the capacity per crushing station compared to competing crushers.

Tagged: Crushing Machinery MexicoCrushing Plant for Sand and Gravel MexicoStone Crusher Mexico

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)