Feed & Product Size of a Crushing Plant

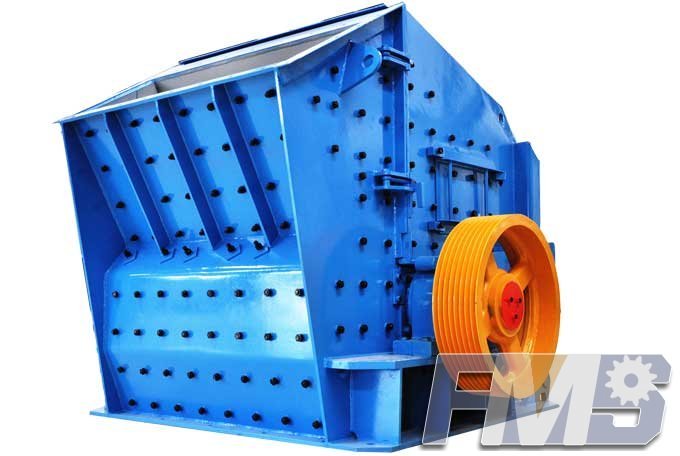

Normally each manufacturer has a range of different crushing chambers for each size of crusher so that there is a wide choice of feed opening and capacities to choose from. The reduction ratio is where the feed size and the desired product size should be considered together. This ratio makes it easy to calculate the number of crushing stages required in the plant to reduce the material to an acceptable size. It is normal to take between 80 and 90 percent of the feed opening’s minimum dimension as the largest feed material size that can be easily accommodated by that crusher. In an optimized operation five percent of feed is usually oversize to the crusher and is screened off by a grizzly from where secondary breaking (by mechanical means) reduces it to manageable dimensions.

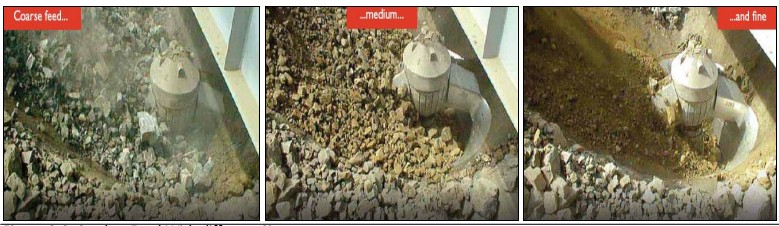

Figure shows different size of crusher feed material rocks which should be regulated so that the crusher feed does not have to be stopped and started because of oversize in the crusher bowl.

The reduction ratio is based on an 80 % passing figure. That is if 80 % of the feed passes 350 mm and 80 % of the crusher product passes 100 mm then the reduction ratio for that operation is 3.5 to 1. It is dependent on the power rate transmitted to the material but also on its Work Index.

Tagged: Product Size of a Crushing PlantFeed Size of a Crushing Plant

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)