Feeding principle of Jaw Crusher

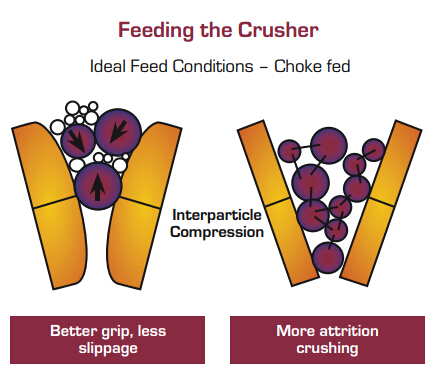

For optimum performance from a Jaw Crusher it is extremely important to pay attention to the way the machine is fed. As the design requires the Crusher to be choke fed, at least 80% of the chamber needs to be full at all times.

In other words, only about 20% of the top of the jaw liners should be visible. In choke feeding, a heavy load of material is fed into the chamber to press down on the material being nipped.

It also extends the life of the manganese liners as much of the impact and abrasion from dribble feeding is eliminated.

Finally, with the fines removed from the feed material, and with a full chamber of material, efficient attrition will ensure production throughput is maximised. Fines in crushing terminology is defined as material sized less than the CSS (closed side setting) and they should be removed by a Vibrating Grizzly Feeder/Scalper installed close to horizontal to keep discharge velocity into the jaw crusher at a minimum and to minimise high impact wear on the jaw liners.

The major point to fully understand in crushing materials is knowledge of the feed material. It is highly likely that material from a quarry in the north of a country is different from material blasted in the south of the country. Wherever possible, a feed gradation should be done to determine its suitability for crushing and for the intended use of the product.

A material analysis will also determine the abrasiveness and hardness of the material which would influence manganese liner life. Hardness of a material is generally referred to as the Bond Work Index and is a measure of grindability of a material and the higher the Bond Work Index (BWI), the harder the material is to crush. Therefore, as the WI increases, so does the power requirement.

Nip Angle

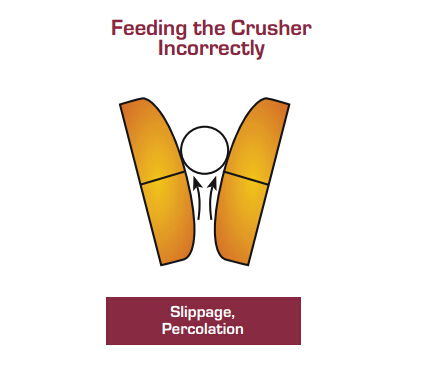

The nip angle of the crusher jaw plates will determine the effectiveness of the machine.

The crushing action takes place low in the jaw cavity and is referred to as the choke point.

If the nip angle is too big then the jaws will not be able to grab the material and often in this case, the material is pushed upwards. This would result in extreme wear on the jaws and a significent production decrease.

When determining the nip angle, the type, bulk density and general material characteristics will be influential in the correct nip angle/crusher selection

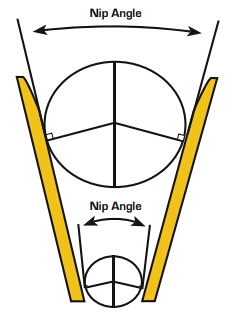

Nip Angle

Nip Angle is the angle created between the fixed and swing jaw liners.

• Range 11˚- 23˚ optimal 19˚ for most material types

• Maximum nip angle occurs at minimum discharge setting with curved liners

• Discharge setting usually expressed as closed side peak to valley or peak to peak dimension

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)