Jaw Crushers Operating Principle

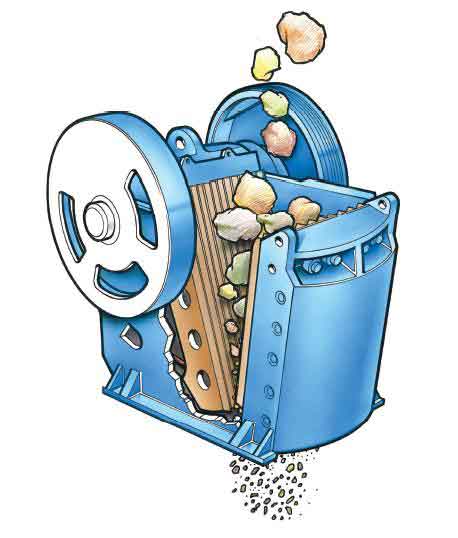

The ore or rock is fed to the crusher where the jaws are furtherest apart, i.e. at the maximum opening or gape. When the jaws come together the ore is crushed into smaller sizes and slip down the cavity. In the return stroke, further reduction of size is experienced and the ore moves down further. The process is repeated till particles having size less than the bottom opening or set pass through as product.

The rule of thumb applicable for operating a jaw crusher with respect to its design characteristics can be summarised as follows:

Feed size = 0.8 - 0.9 x gape

Reduction ratio, R = 1:4 to 1:7

Throw, LT = 1-7 cm

Speed = 100 to 359 rpm

Frequency of stroke, v = 100 -300 cycles per min

Length of stroke = 0.0502 x gape0.85

In practice, the operator has to decide on the spacing of the set at the discharge end. This setting has to include the maximum and the minimum positions that the bottom has to open during the oscillation of the bottom end of the jaws. The manufacturer of jaw crushers provides all the controls to adjust these settings. The actual distances are best measured by taking a soft metal, like lead or a ball of aluminium foil, and squeezing it between the jaws at the desired width forming a kind of template. This piece of lead metal is used to check the change of setting during operation.

During the operation of a crasher the bulk density of the material increases and the particle size decreases. With time, wear on the plate surfaces develops resulting in a change to the crusher surface profile. This could alter the throughput and size of the crusher product.

The mechanism of movement of rocks down the crusher chamber determines the capacity of jaw crushers. The movement can be visualised as a succession of wedges (jaw angles) that reduce the size of particles progressively by compression until the smaller particles pass through the crusher in a continuous procession. The capacity of a jaw crusher per unit time will therefore depend on the time taken for a particle to be crushed and dropped through each successive wedge until they are discharged through the bottom. The frequency of opening and closing of the jaws therefore exert a significant action on capacity.

Tagged: Jaw Crushers Operating PrincipleJaw Crusher Operating FunctionsJaw Crusher Machine

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)