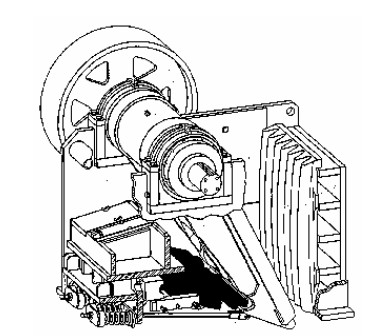

Blake Crusher,Blake Stone Crusher,Blake Type Jaw Crusher

Blake type jaw crusher, primary crushers in the mineral industry; attains maximum amplitude at the bottom of the crushing jaws as the swinging jaw is hinged at the top of the frame. These crushers are operated by and controlled by a pitman and a toggle. The feed opening is called gape and opening at the discharge end termed as the set. The Blake crushers may have single or double toggles. The toggle is used to guide the moving jaw. The retrieving motion of the jaw from its furthest end of travel is by springs for small crushers or by a pitman for larger crushers. During the reciprocating action, when the swinging jaw moves away from the fixed jaw the broken rock particles slip down and are again caught at the next movement of the pitman and are crushed again to even smaller size. This process continued till the particle sizes becomes smaller than set; the smallest opening at the bottom. For a smooth movement of the moving jaws, heavy flywheels are used.

Principle of Operation

Rock flows into the space between two vertical jaws. One jaw is stationary. The other jaw moves in an elliptical-downward motion toward the stationary jaw while crushing, and upward and away from the stationary jaw allowing the crushed material to exit. Jaw crushers are primary units, that receive material directly from the quarry.

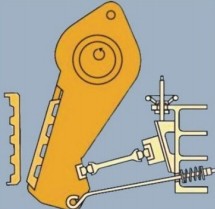

Types of Blake Crusher

- Single toggle type: - A single toggle bar is used in this type of crushers. Comparatively lighter jaw crushers use single toggle as they are cheap.

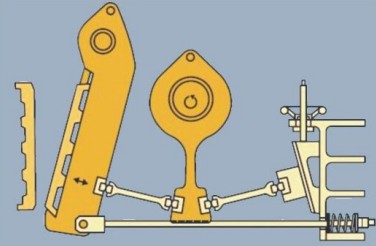

- Double toggle type: - One extra toggle bar is attached here. Commonly used in mines as ability to crush materials is excellent, including tough and abrasive minerals. To crush larger material, Blake type jaw crushers are preferred. The characteristics of such crusher are:

1. Larger, rough, massive and sticky rocks can be crushed.

2. They are easy to maintain .

3. It is very simple to adjust and prevent much of wear and are easy to repair.

4. Moving jaw can be reinforced with high tensile manganese to crush very hard rock

Tagged: Blake Type Jaw CrusherBlake CrusherBlake Stone Crusher

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)