Advantage of VSI Vertical Shaft Impact Crusher of Formats

Higher capacity

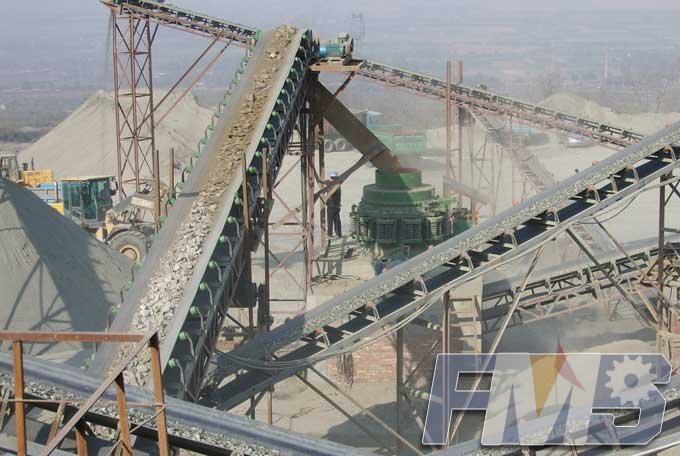

The VIS Vertical Shaft Impact Crusher are the solution for current and future operating conditions in which output and productivity demands are increasingly stringent.

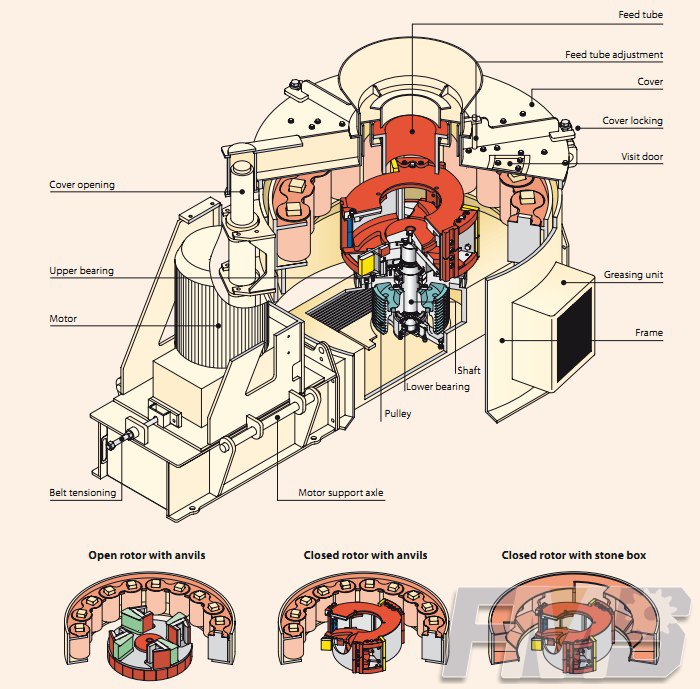

Our engineers have optimised machine layout to maximise compactness with a single drive shaft to make the machine even stronger and more powerful without unbalancing the rotor. A lot of ef ort has gone into redesigning the rotor to minimise wear while increasing crushing reduction factors and capacity. Vertical Shaft Impact Crusher VSI enable to achieve a higher reduction with fewer crushing stages, lowering your capital costs and saving energy.

Higher quality

Formats international reputation is based on crushing plant eifficiency and quality. VSI vertical shaft crushers are firmly rooted in this tradition.

On-going collaboration with many research laboratories has now made it possible to bring you state of the art technical innovations in terms of the durability of wear parts (shoes, liners and and impact anvils) and the reliability of the mechanical components used in the crushers (drive shaft, bearings, etc.)

Unique chamber geometry

Extremely modular, VSI vertical shaft crusher layouts can, in the same frame, be changed without major modifications to open rotor set ups with anvils or closed rotor solutions with stone bunkers. They feature many technical benefits such as the tapered shape of the anvils making it possible to turn them when they are half worn and to boost the payload, thereby improving productivity. The specific shape of the closed rotor reduces rotor wear and maintenance costs by increasing reduction factors.

Easy to maintain with high security level

The frame is closed by a hydraulic jack. The in- terior of the crusher is accessed via safety doors behind the lid. Particular care has been taken to secure and simplify plant maintenance. Drive pulleys are no longer changed under the crus- her with all the risks this implies, but directly fa- cing the operator. A central lubrication system optimises bearing greasing and reduces the number of servicing interventions. Vibration sensors shut down the crusher immediately if a problem is detected.

Application flexibility with environment concern

No drastic modifications are required if, for any reason, you decide to change your VIS impact crusher tasking. Machine design limits dust emissions by reducing and recirculating air flows within the crusher confinement hood. VIS vertical shaft crushers are all pre-equipped for fitting a wide range of dust traps.

Easy to operate

Once set up for a specific mission, VSI impact crushers do not need fine tuning to maximise performances.

Formats global after-market network means help is always close by. If you ever have any questions or problems, we’re always ready to get you operating at peak efficiency in no time.

Tagged: VSI Vertical Shaft Impact CrusherAdvantage of VSI CrusherStone Vertical Shaft Crusher

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)