Grinding Mill Liner for Sale

The design of a liner is driven by the material of construction and the application, and is limited by casting, moulding, and handling constraints. For large mills with wide inlet trunnions in excess of 1.5 m, liner handling machines are now in common use, and this has allowed the evolution of large integral liner blocks, each weighing up to 1.5 t. This holds great advantage for minimising relining time, as there are fewer blocks to handle.

For smaller mills, the liners have to be handled and installed manually, so smaller blocks with removable lifter bars are generally favoured. Following is a list of the primary types of liners, including comments on their application, advantages, and disadvantages:

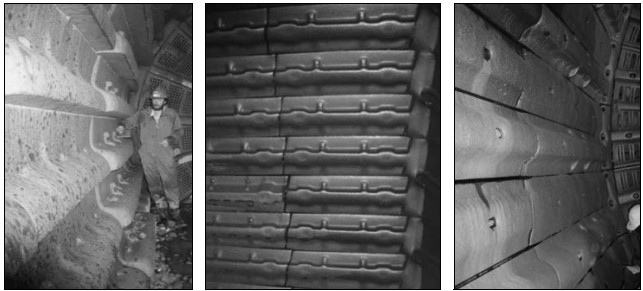

- Solid liners: These types of liners have an integral lifter and liner, as shown in Figure. They have fewer pieces and are easier to install, but they tend to have a high scrap weight, as once the lifter section is worn down, liner performance drops and necessitates change-out.

- Removable lifter: In a liner with a removable lifter, the lifter can be changed rather than the complete liner thereby maximising liner life and assisting in manually relined mills. The drawback is that there are more pieces to be installed, and the liners can move during relining. If they are not well secured against the backing liner, the lifter can shift and work loose; this is especially a problem if the bolts begin to stretch.

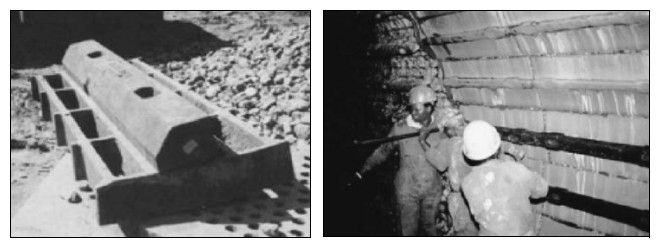

- Grid liners: Pocketed grid liners is a system (that appears to be unique to Southern Africa) where the grinding media packs in the grid structure and forms an integral part of the liner. Often the liners have a flat profile, suited to the high speeds (85% to 90% of critical) at which most of the older mills operate. These liners have been demonstrated to be economically unbeatable for highly abrasive ores in small- to medium-size mills (Powell 1991a). They are lightweight and make use of the grinding media hardness to provide an effective wear material. They must be manufactured in manganese steel to wedge the steel balls, but the manganese steel spreads on impact and can make removal difficult. Safety aspects should be considered because of the risk of balls dislodging when the mill is entered for inspection or relining. The liners require a thorough hosing down to prevent this.

- Wedged liners: Wedged liners were common in the first half of the last century but are dangerous to install and no longer used. Liner blocks are now wedged in by bolted lifter bars, which allows simple castings of the liner blocks.

- Integral wave blocks: These are commonly used in ball mills, and the profile of the liners has become sufficiently sophisticated to enable the liner profile to be maintained as the liner wears.

- Uni-direction profiled liners: The lifter has different leading and trailing profiles . The profile can be better customised to suit mill speed and filling and therefore optimise performance. It allows more material in the lifter for a given base width, but the mill must only run in one direction.

- High–low double-wave ball mill liners: These liners are a refinement of the wave liner. This was applied to Cadia Hill gold mine through evaluation of their existing wear profile and wear rate, and it provided a more consistent wear profile through the liner’s working life. The correct wave face angle needs to be calculated and applied because an incorrect angle can lead to ball segregation and loss of grind.

Previous: High Pressure Grinding Roll for Sale

Next: Grinding Equipment Manufacturers,Mineral Grinding Equipment for Sale

Tags: Grinding Mill Liner

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)