Selection the Primary Crushing Equipent - How to Choose The Primary Crusher

The main purpose of a primary crusher is to reduce the material to a size that allows its transportation on a conveyor belt. In most crushing installations producing aggregates, a jaw crusher carries out the primary crushing. Plants with very high capacities normally use a primary gyratory crusher. When the material is easy to crush and not very abrasive, an impact crusher may be the best choice for primary crushing.

Crushing Plant

Crushing PlantOne of the most important characteristics of a primary crusher is its capacity for accepting feed material without bridging. A large primary crusher is, naturally, more expensive than a smaller one. Therefore, the investment cost calculations for primary crushers are compared together against the total costs of primary stages, including quarry face clearing, blasting, and drilling costs. In many cases, dump trucks trans- port the rock to a stationary primary crusher. This may be an expensive solution. Amortisation, fuel, tyres, and maintenance costs can be included when the vehicles are in high demand. In modern operations, the use of mobile primary crushers that can move alongside the rock face is, in many cases, the most economical solution.

A stationary primary crusher can be transformed into mobile equipment with the help of a track system (with crawlers). A track-mounted primary crusher may be an interesting solution economically in cases where the equipment needs to be constantly repositioned in the quarry. However, it can be a slightly more expensive solution in terms of investment and maintenance. There may be potential for cost savings in material loading and transportation. If these savings are realised, the potential savings over traditional methods could be up to 25%. All this means that these matters have to be analysed case by case, and there are effective tools available for this.

Primary Jaw crushers

In terms of the size of the feed opening, the client gets a better return on investment when the primary crusher is a jaw crusher. That means less drilling and blasting because the crusher accepts larger boulders. The disadvantage of this type of crusher, when high capacity is required, is the relatively small discharge width, limiting the capacity as compared with the discharge circuit of a gyratory crusher. Jaw crushers are mainly used in plants producing up to approximately 1600 t/h.

Primary gyratory crushers

The primary gyratory crusher of ers high capac- ity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of the jaw crusher) and the continuous operation principle (while the reciprocating motion of the jaw crusher produces a batch crushing action). The gyratory crusher has no rival in large plants with capacities starting from 1200 t/h and above. To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier. Also, primary gyratories require quite a massive foundation.

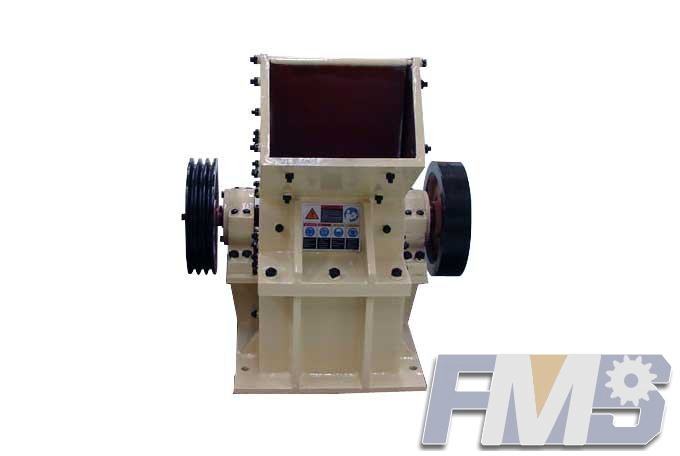

Primary Impact Crusher

The primary impact crusher of ers high capacity and is designed to accept large feed sizes. The primary impact crushers are used to process from 200 t/h up to 1900 t/h and feed sizes of up to 1830 mm (71") in the largest model. Primary impact crushers are generally used in nonabrasive applications and where the production of i nes is not a problem. Of all primary crushers, the impactor is the crusher that gives the best cubical product.

Tagged: Primary Jaw crushersPrimary Gyratory CrushersSelection the Primary CrusherChoose The Primary Crushing EquipentPrimary Crushing EquipentPrimary Impact Crusher

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)