Mineral Sizer Crusher for Sale

The twin roll mineral sizer is a development of the on-belt coal crushers and Stammler sizers. The unit consists of two counter rotating shafts mounted in a frame. On the shafts are mounted several rows of sizing teeth which draw the rock down into the crusher. The shafts are driven by an electric or hydraulic motor through a gearbox and fluid couplings. For large capacity crushers, up to about 8’00t/h, there is a motor to drive each shaft. The units are of modular construction which allows each machine to be made up to the purchaser’s requirements. The number of rings and the number of teeth per ring can be varied to suit. Detailed specifications of each machine are decided upon by its specific duty.

A wide range of raw materials required for the making of cement are suitable to be crushed in a sizer. These crushers perform well with very sticky clay and also marl with a high moisture content and are to a large extent self-cleaning. Such a machine willalso crush medium hard limestone having brittle characteristics successfully. Material with a high abrasive index, however, will accelerate wear on the pick heads and can result in them being replaced at frequent intervals. The machine is slow running andwith few moving parts which minimises wear and replacement of parts. If a hard rock or piece of tramp iron enters the crusher the rotating shafts will stall when the teeth grip it rather than force such material through the crusher. The shafts are then counter rotated and the offending piece can be removed. Similarly if bridging takes place above the shafts they can be counter rotated until the teeth grip and the material is dislodged. Units have been installed at an angle to assist very hard material to run off over the shafts rather than be crushed and damaging the shafts or picks.

The sizer accepts material in through the top of the unit. The two inward rotating shafts with their rows of teeth draw the oversize down into the crusher while permitting the controlled passage of undersize without further reduction in size. This eliminates the need for a scalper in front of such a primary crusher. Material is broken in a sizer principally by tensile stress and shear. This reduces the quantity of fines produced by the crushing action. All breaking forces are contained in the machine. This has the effect of reducing the foundations necessary to support the crusher. It is very well suited to mobile mounting on crawlers, skids or even wheels.

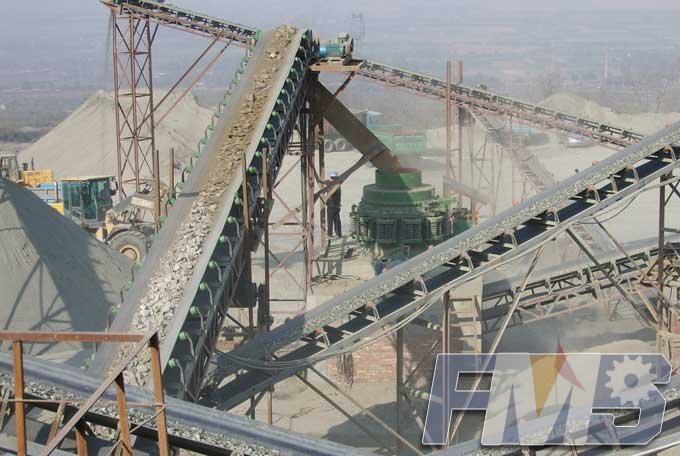

These crushers are compact the space and particularly the vertical dimensions are by far smaller than for the equivalent capacity jaw or hammer crusher. Their vertical dimension is small enough that they have been installed at transfer points between conveyors. It does not require a feeder; material can be loaded directly into the crusher chamber. However wear rates and the incident of broken teeth can be considerably increased by this action and it is not to be considered “good practice”.

The sizer does not have a large reduction ratio and in projects where such a crusher has been considered then thought has also to be given to having a secondary unit. Due to its small size the space taken by two such crushers is minimal; especially whencompared to other types of crusher. It does, however, make the cost of the crushing system equal or higher to the more conventional single stage systems that are in use at many of our plants.

PRINTGET PRICEPrevious: Excellent Double Roll Crusher Suppliers in China - Formats Construction Machinery

Next: Cone Crusher With Overload Protection Device for Sale

Tags: Mineral Sizer CrusherMineral Sizer Crushing MachineMineral Sizer

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)