Energy Consumption in Crushing and Grinding

The energy input to size ore fragments is large. Overall reduction, performed in a series of stages may be from an eighty percent feed size passing of 40 cm (15.8 inches) to a final product size of 270 to 325 mesh (.053 to .045 mm). A lot of energy is expended to accomplish this, and it is not a particularly efficient, with much of the energy input being dissipated as heat. It has been estimated that grinding efficiency may be as low as one percent.

The third theory of comminution developed by Bond (1952) is still used today, although there have been recent advances (King and Schneider, 1995). Using this theory, energy requirements to reduce fragments from an 80% feed size to an 80% product size can be calculated.

The Bond equation of comminution is stated as follows:

W = 10Wi(1/P5-1/F5) , where

W = work input, kwh/ton

Wi = work index for the specific rock type, kwh/ton

P = 80% passing size of the product

F = 80% passing size of the feed

One reason for using Bond’s third theory is that work index Wi has been measured and reported for many rocks.

Using this relationship one can study the work input required for different feed sizes and work indices in the stages of comminution. In the current study Wi is held constant throughout the stages, although it may, in fact, vary. Provided consistency is maintained the trends in energy consumption and cost will be correct.

As a base case, we assume that taconite ore is being blasted with a heavy ANFO (HANFO) having absolute weight strength of 3.35 MJ/Kg (801 cal/gm). The 80% passing size of the blasted ore has been measured and found to be 40 cm (15.75 inches). The ore passes through primary and secondary crushing and grinding. The final product is 80% passing 270 mesh.

Bond has published a Wi for taconite of 14.87 (1961). This value is used in these base case calculations.

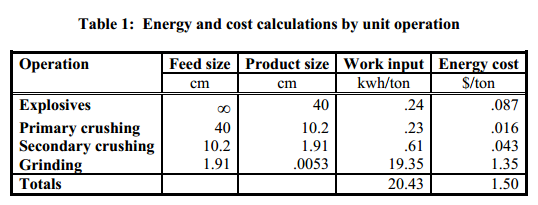

Table 1 shows the feed and product size, the calculated total energy input, and the energy cost for each unit operation. The explosive cost is based on the powder factor of 0.33 kg/tonne (0.65 lbs/ton) and an explosive cost of $0.264/kg ($0.12/lb). Electric energy cost is assumed to be $0.07 per kwh.

By far the greatest work input is in grinding. Size is reduced by a factor of 360. In primary crushing, it is reduced by a factor of four and in secondary crushing by about five times. Clearly, changes in blasting that reduce grinding requirements will have the biggest impact for energy savings.

The work input shown for blasting is calculated by the Bond equation. The actual energy input is .33 kg/ton, or .31 kwh/ton. Thus, the efficiency compared to Bond is 77 percent. This is likely due to the variable nature of rock and the transmission of the energy, and the possibility that Wi is greater than 14.87 in the unblasted state. The cost for the explosives however is that associated with the powder factor of .31 kwh/ton.

From an energy consumption viewpoint, it is clear that blasting that decreases the Bond work index will produce large savings if that reduction carries through to grinding.

Tagged: Crushing and Grinding

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)