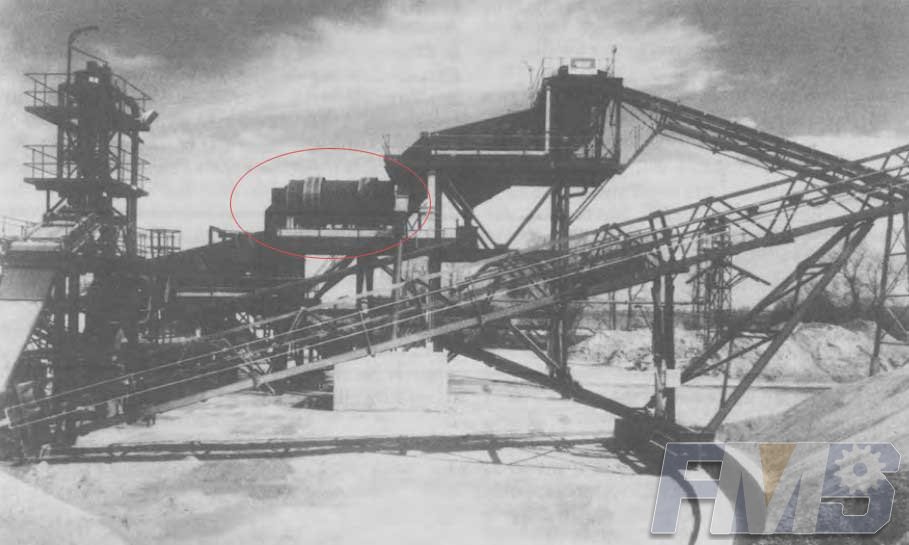

Barrel Washer for Sand and gravel

The barrel washer comprises a cylindri- cal drum rotating on an axis slightly inclined to the horizontal. The drum is lined with wear resistant material which may also form lifters of linear or spiral form. A depth of aggregate and water is retained in the drum by an annular dam at the dis- charge end. Rotation of the drum creates vigorous agitation of the feed material with water and transport of the aggregate through the washer. The overflow from the washer usually discharges onto a vibrating screen equipped with water sprays to effect separation of slurried clay and fine aggregate from coarser washed aggregate. In cases where the feed contains a high proportion of sand the washer may be preceded by a wet screen also.

The underflow of these screens passes to a classifier which will separate the clays from the fine aggregate which will then often be suitable for direct sale as fine concrete aggregate. Alternatively, a second classifier is employed to divide the sand into coarser and finer fractions often called 'sharp' and 'soft' sand respectively. As already discussed, this classifier achieves a separation between the coarser, denser and more rounded mineral particles directed to the underflow or sand product and the finer, less dense and flaky particles contained in the overflow. Thus, the underflow can be a finished coarse sand product comprising competent mineral particles without impurity. The overflow, however, may comprise a mixed suspension of fine, but competent, sand parti- cles and larger particles of weak, porous and lower density minerals or those exhibiting very flaky shape. This is especially the case where the deposit contains lignite, shale and coal which will tend to con- taminate the fine sand in this manner. Fortunately these larger undesirable particles can be relatively easily removed by screening the overflow through sieves of narrow aperture (less than 1 ram) such as sieve bends to produce a clean fine sand.

Tagged: Barrel Washer for aggregateWashing barrel MachineWashing scrubber Machine

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)