Wet Grinding of Raw materials,Raw Materials Grinders

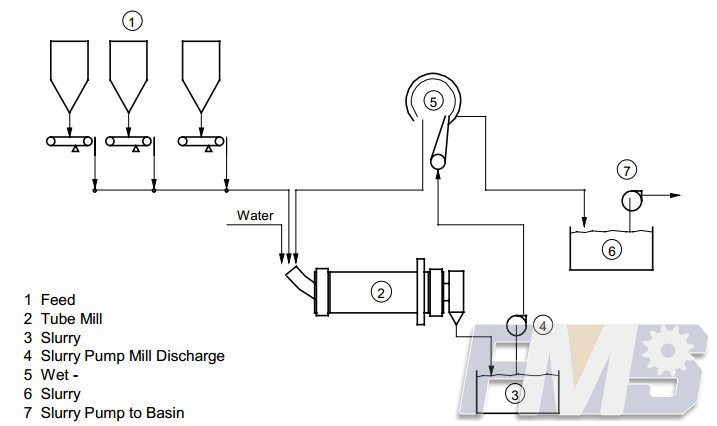

Wet grinding is used only in combination with a wet or semi-wet kiln system. The raw material components are ground with the addition of water to form a slurry. To achieve the required slurry fineness i.e. to comply with modern quality demands, mainly closed circuit mill systems have to be considered.

Wet Raw Grinding with Tube Mill in Closed Circuit

Raw materials such as chalk, marl or clay, which are sticky and of high inherent moisture content, are soft and as a first stage of preparation they may be ground in a wash mill. Water and crushed material are fed to the wash mill and broken down into slurry by shearing and impact forces imparted by the rotating harrows. Where sufficiently fine the material passes through screens in the wall of the wash mill and is pumped to subsequent storage. To achieve the required slurry fineness further grinding in a tube mill is usually required, especially if a secondary raw material such as sand is to be added.

To reduce kiln fuel consumption water addition during the raw material grinding is controlled to the minimum necessary to achieve the required flow and pumpability characteristics of the slurry.

Beside the closed circuit tube mill, the same mill type is used as an open circuit mill.

Tagged: Raw Materials Grinderswet grinding cementwet cement grinder

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)