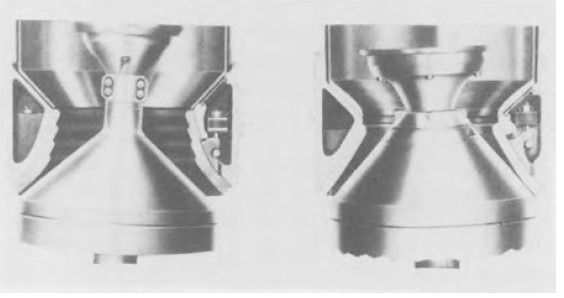

Types of Cone Crusher:Standard and Short-Head Cone Crusher

The cone crusher is available in several forms to most suit the requirements of the secondary and tertiary stages of comminution. The secondary cone (standard cone) crusher has a steeply inclined, sometimes stepped, crushing chamber formed by the concave and a flatter less steeply inclined conical crushing member. The reduction ratio achieved varies from 4:1 to 8:1. The tertiary, short-head-cone, crusher has both crushing chamber and cone steeply inclined to promote the gravitational flow of more finely sized material. The reduction ratio varies from 4:1 to 6:1. A great deal of experience and expert knowledge is now available to optimize the detailed design of the crushing chamber, eccentric throw, etc., in terms of feed size distribution, desired product, power consumption and liner life.

Standard (left) and Short-Head (right) Cone Crusher

The maximum particle size of the product is largely controlled by the distance between the mantle and concave at the open side of the crusher. Since this clearance cannot be easily measured the closed side setting is usually determined by crushing a piece of malleable lead. As a 'rule-of thumb', the maximum product size is approximately twice the closed side setting. This may be varied within limits by either raising the cone or lowering the concave assembly. Both methods are employed as in (a) the use of hydraulic support of the eccentric shaft and (b) machine threads or hydraulic support of the crushing chamber assembly. Both provide a method for compensating for wear of the liners and providing overload release in the event that uncrushable material, e.g. tramp metal is contained in the feed. Moreover, hydraulic support provides a means of automatic control upon product size and/or maximum power input without fear of overloading the crusher. This can result in significant improvements in plant productivity.

It is common practice to operate secondary and tertiary crushers and grinding mills in closed circuit with a sizing device such as a screen or a classifier as appropriate. The product from the comminution device passes to the sizing unit where oversize particles are removed and then recirculated to the comminution device. With such a circuit it is possible to control the top size strictly, to prevent excessive generation of undesirable fines and to save upon power consumption.

Tagged: types of cone crusherStandard Cone CrusherShort Head Cone Crusher

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)