Dodge Jaw Crusher

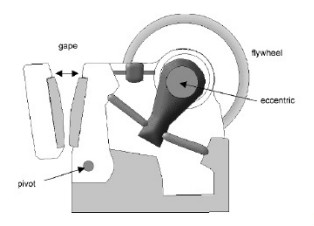

The Dodge Crusher finds favor as the initial crusher in small plants, and as a secondary crusher. As shown in the sectional view (figure 1), it consists of a heavy frame carrying a movable jaw supported in bearings at the bottom. The jaw is one side of a triangular shaped lever, and receives its motion from an eccentrically operated vertical pitman, the jaw movement being practically nothing at the bottom where supported and increasing to a maximum at the top of the opening. Its capacity is governed by the opening at discharge point, but weight for weight the Dodge will handle and crush a larger piece of rock than any other crusher. It works well with dry ores and those free from talc and clay; it is simple and easily operated and is especially adapted to small producing mines.

Figure 1. Dodge Jaw Crusher

The movable jaw is pivoted at the bottom and connected to an eccentric shaft. The universal crushers are pivoted in the middle so that the jaw can swing at the top and the bottom as well. Maximum amplitude of motion is obtained at the top of the crushing plates. Dodge type crushers are not used for heavy duty and commonly found in laboratories.

Working Principle of Dodge Crusher

The mechanism of Dodge jaw crusher is based on the concept “crushing without rubbing”. Jaw crushers consist of two jaws. One fixed and the other reciprocating. The opening between them is largest at the top and decreases towards the bottom. The pitman moves on an eccentric shaft and swing lever swings on centre pin. The rock is thrown between two jaws and crushed by mechanical pressure

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)