Roller Crusher

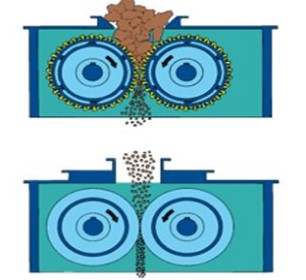

Roller crusher consists of a heavy cast frame supporting one or two rolls. Each roll comprises a shaft, a roll center made of cast steel and a shell. This shell can either be smooth or corrugated or have teeth of a wear resistant metal inserted into slots on the shell. Diameters of rolls can vary from 350 mm to 2.0 m and in width up to 2.0 m. Rolls are independently driven by a flywheel type multiple V-belt sheave. One set of bearings is made to slide horizontally on the frames. These moveable bearings are spring loaded to provide a safety relief for excessive pressures. Springs are pre-set to a working pressure for which the machine is designed. The bearings are drawn up against locating shims to establish the gap between either, a roll and breaking plate or two rolls. Speeds of roller crushers vary according to the material being crushed. Medium rotor speeds, a tip speed of 8.0 to 10.0 m/s are used with materials that are difficult to comminute. For materials of a plastic consistency a lower rotor speed preferred (4.0 to 8.0 m/s). Clay crushers (no longer in general use) had a tip speed of only 1 to 2 m/s. Metal used for the teeth can be manganese steel or a boron alloyed carbon steel as they are subject to high wear rates. Teeth have to be profiled by means of special welding materials at intervals depending on the abrasiveness of the material and how the maintenance is carried out. The interval can be six weeks or six months. Number and size of teeth on toothed roller crushers depend on the crushing requirements. A primary roller crusher will have larger teeth with fewer per row and less rows than a secondary crusher. Teeth of different heights a re often used on primary crushers. The higher teeth are known as ‘slugger’ teeth and the shorter ones as ‘regular’ teeth. The slugger teeth are designed to grip the larger rocks dragging them between the crushing faces where they are sheared by the regular teeth. The crushing action of slugger teeth is termed sledging. Sledging is the breaking of material as a sharp stroke is delivered to a particle while it is prevented from moving by being in contact with an opposing surface either fixed or moving. In general the roll sizeof a crusher is governed by the feed size, crushing strength and friability of the feed rock. In choosing the appropriate crusher size the aim should be to have a one to one ratio between the maximum feed size and the roll diameter. Crusher throughput and product particle size are mainly governed by the distance between the rolls and their width. In these crushers three methods of reduction occur. Entering the crusher chamber the material is impacted by the teeth of the revolving roll. As the turning roll compresses the material against the breaker plates or other roll the teeth shear the material. Finally as the teethof the roll come together the rock is compressed.

Roller crusher consists of a heavy cast frame supporting one or two rolls. Each roll comprises a shaft, a roll center made of cast steel and a shell. This shell can either be smooth or corrugated or have teeth of a wear resistant metal inserted into slots on the shell. Diameters of rolls can vary from 350 mm to 2.0 m and in width up to 2.0 m. Rolls are independently driven by a flywheel type multiple V-belt sheave. One set of bearings is made to slide horizontally on the frames. These moveable bearings are spring loaded to provide a safety relief for excessive pressures. Springs are pre-set to a working pressure for which the machine is designed. The bearings are drawn up against locating shims to establish the gap between either, a roll and breaking plate or two rolls. Speeds of roller crushers vary according to the material being crushed. Medium rotor speeds, a tip speed of 8.0 to 10.0 m/s are used with materials that are difficult to comminute. For materials of a plastic consistency a lower rotor speed preferred (4.0 to 8.0 m/s). Clay crushers (no longer in general use) had a tip speed of only 1 to 2 m/s. Metal used for the teeth can be manganese steel or a boron alloyed carbon steel as they are subject to high wear rates. Teeth have to be profiled by means of special welding materials at intervals depending on the abrasiveness of the material and how the maintenance is carried out. The interval can be six weeks or six months. Number and size of teeth on toothed roller crushers depend on the crushing requirements. A primary roller crusher will have larger teeth with fewer per row and less rows than a secondary crusher. Teeth of different heights a re often used on primary crushers. The higher teeth are known as ‘slugger’ teeth and the shorter ones as ‘regular’ teeth. The slugger teeth are designed to grip the larger rocks dragging them between the crushing faces where they are sheared by the regular teeth. The crushing action of slugger teeth is termed sledging. Sledging is the breaking of material as a sharp stroke is delivered to a particle while it is prevented from moving by being in contact with an opposing surface either fixed or moving. In general the roll sizeof a crusher is governed by the feed size, crushing strength and friability of the feed rock. In choosing the appropriate crusher size the aim should be to have a one to one ratio between the maximum feed size and the roll diameter. Crusher throughput and product particle size are mainly governed by the distance between the rolls and their width. In these crushers three methods of reduction occur. Entering the crusher chamber the material is impacted by the teeth of the revolving roll. As the turning roll compresses the material against the breaker plates or other roll the teeth shear the material. Finally as the teethof the roll come together the rock is compressed.

Tagged: Roller CrusherRoller Crusher ManufacturersRoller Crusher for Sale

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)