Feed Drying of Crushing Plant

Crusher with Dryer

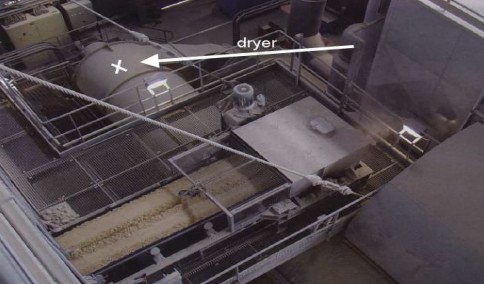

In compound and impact crushers the contact plates can be heated to about 120 degrees Celsius. Moisture contained in the sticky material evaporates when it comes into contact with these plates and falls off. The purpose of this devise is not to dry the feed but to prevent build-up of material on the contact plates and reduce the crushers ability to crush. An alternative method of drying the feed is to blow hot air through the crusher unit as it is working. These machines are capable of drying a feed containing 20 % moisture to a product containing 0.5 % moisture whilst maintaining a high reduction ratio. Inlet slide plate and impact aprons of crushers can be designed for heating of the material that comes into contact with these surfaces. Feeds with a moisture content of 15 % can be crushed with few problems.

Tagged: Feed Drying of Crusher

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)