Clinker Grinding Machine for Sale

In the manufacture of Portland cement, clinker is lumps or nodules, usually 3–25 mm in diameter, produced by sintering limestone and alumino-silicate (clay) during the cement kiln stage. Portland cement is made from exact proportions of materials containing calcium, silica, alumina, and iron. Approximately 1.5 t of raw materials are required to produce 1 t of finished cement. Grinding is an important operation in the cement making process, occurring at the beginning and end of the production cycle. The last stage in the process of manufacturing portland cement is the finish grinding of clinker together with small amounts of gypsum and some admixtures. The principal objectives of clinker grinding are to promote the hydration of cement and to ensure complete coating of inert aggregates. The fineness of the cement affects the placeability, strength, and permeability of the concrete properties. The finer the grind, the more reactive the finished cement. Therefore, every type of cement must exhibit a particular degree of fineness to meet its quality specification.

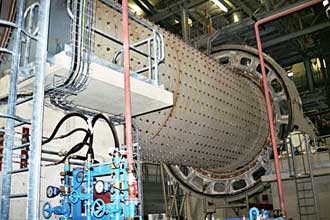

Equipment Used for Clinker Grinding

We have almost all types of mills for grinding clinker include ball mill, tube ball mill, vertical mill, roller mill, hammer mill, high-pressure grinding rolls, etc.

For most of the twentieth century, the dry-grinding circuits for the production of finished cement from cement clinker consisted of two-compartment tube mills and air separators. Alternative mills such as the HPGRs, VRMs, and the Horomill have been applied in recent times to improve the grinding efficiency. Significant energy savings are reported in applications that utilize these mills, the Vertical Roller Mills being the most widely used. During this period, the design of the air separators has evolved from the very inefficient static separators to the highly efficient dynamic separators. These separators play a crucial role in improving the overall energy efficiency of the cement-grinding circuits.

PRINTGET PRICEPrevious: Primary Gyratory Crusher for Mineral Processing for Sale

Next: Attrition Crusher,Attrition crushing Machine for Sale

Tags: Clinker Grinding MachineClinker Grinding Mill ManufacturersClinker Mill Manufacturers China

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)