HPGR in Stage Crushing and Ball Mill Circuits

HPGR may be used as a substitute for the tertiary cone crushing in stage crushing/ball mill circuits. The advantages include the high unit capacity, high reduction ratio and possible power efficiency benefits in subsequent grinding.

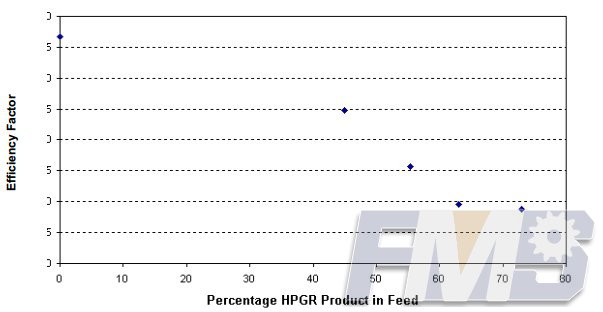

Figure 2 indicates that an SABC circuit operating on Boddington diorite ore was expected to consume over 1.35 times the power predicted by Bond formulae due to the high ore competency. Secondary crushing and partial HPGR of SAG mill feed improved power efficiency. However, three stage crushing with the last stage using HPGR followed by single stage ball milling is expected to result in a comminution circuit that uses between 95% and 100% of Bond predicted power.

HPGR present a significant opportunity if the high capacity HPGR units can be operated and maintained at a lower cost than multiple short head cone crushers. The acceptance of HPGR in main stream mineral processing of competent ores relies entirely on maintenance and wear efficiencies and associated costs. Presently the risks associated with HPGR are considered by many to be greater than the possible benefits.

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)