Air Classifier of Grinding Mill

Classification in the clinker grinding circuits is achieved using the air classifiers. Development of the air classifier was based on the operating principles of two devices, the simple expansion chamber and the Mumford and Mood separator.

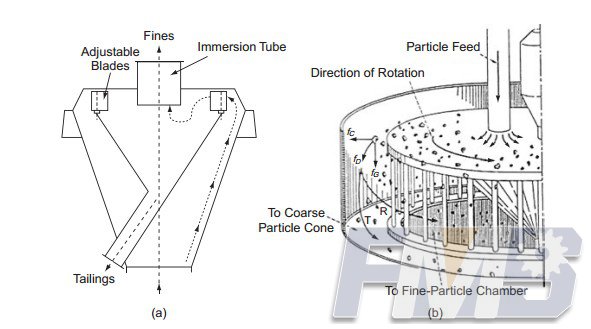

There are two types of air classifiers, dynamic and static. Static air classifiers are an old technology without moving parts. Classification is achieved by changes in air velocity and direction. The principle of operation is shown in Figure 6a. The airstream carrying the particles is converted from a directional flow through the outer cone into a rotating flow by guide vanes. The particles are subject to a centrifugal force—the coarse particles moving to the outer wall of the inner cone and collected in a bin, while the fine particles leave with the air and are sent to a dust collector. The product size can be altered to some extent by changing the angle of the vanes, but the efficiency is low and static classifiers can be regarded more as grit separators than efficient classifiers.

Schematic of the static air classifier(a) and separation mechanism in a dynamic air classifier(b)

Dynamic classifiers have both moving and fixed internal parts. The dynamic air classifiers utilize a distribution plate to disperse the feed material into the separation zone. Thus a particle of material is subjected to three forces: centrifugal force from the distribution plate, uplift from the air current, and gravity. Figure 6b indicates the forces acting on a particle in a dynamic air classifier.

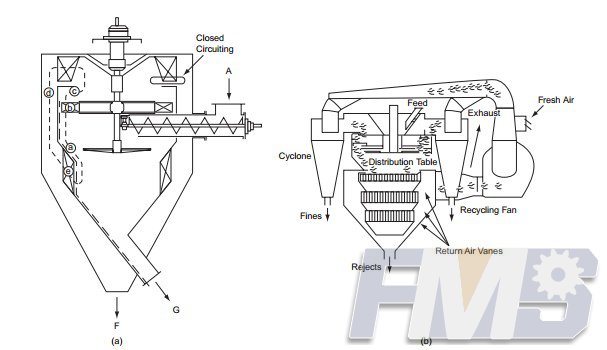

Dynamic classifiers have evolved through three generations, each being significantly better than its predecessor. The first-generation classifier had a distributor plate, and the air circulation in the classifier was provided by a vertically supported rotor. The main problems with the first-generation classifiers were that the circulating air became very hot, fine particles were not removed from the recycling air, and the control of the product was very difficult. Figure 7a shows a simplified sketch of a first-generation air separator.

First-generation dynamic air separator(a) and second-generation dynamic air separator(b)

The second-generation classifier is based on the same operating principles as the first but an external fan is used to circulate the air and a cyclone is used to remove fine particles. Greater product control is possible due to the ability to adjust the rotor speed and air velocity separately.

The third-generation separators are highly efficient separator devices. The feed material to the separator is delivered as a dispersed curtain of particles, and the horizontal air flow to the separator results in uniform separation performance across the unit. The fine particles pass through a rotating cage before going to the fine product. The bars of the cage assist in the performance of the separator.

Almost all of our products are equipped with efficiently air separation, if you need more information, please contact us.

Tagged: Air Classifier ManufacturerAir ClassifierAir Classifier Mill

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)