Stone Crusher in Iraq

Iraq, officially the Republic of Iraq, is a country in Western Asia encompassing the Mesopotamian alluvial plain, the northwestern end of the Zagros mountain range, and the eastern part of the Syrian Desert.

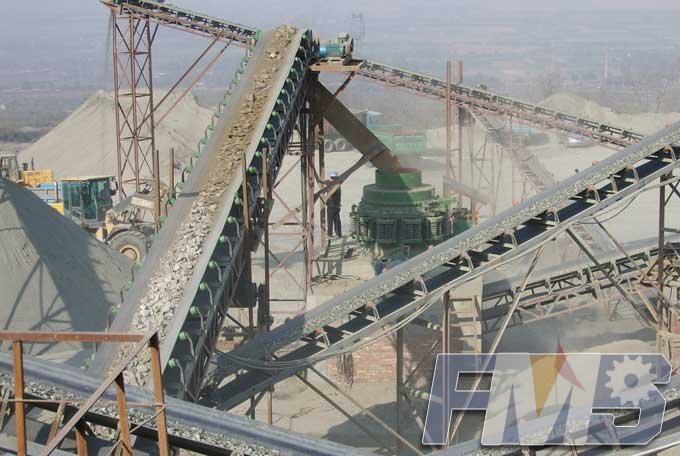

We are professional manufacturer of crushing and grinding machine like jaw crusher,cone crusher,impact crusher, vertical mill, roller mill, ball mill and so on. We have provided a grinding production line for Iraqi customers(ver figure below ).

If you need a grinding line, please contact our online service or leave us a message. If you need a crushing line or a single crushing machine, Here to introduce you to one of our best selling crusher: cone crusher. For more information, you can view our product catalog, or contact us.

Cone Crusher for Sale in Iraq

This type of crusher is very commonly used as a secondary crusher and usually either of the “supported head type’’ or “suspended head type”. Cone crushers with supported heads and feed plates on top of the cone were originally developed by Symons in the USA. They consist of an external fixed bowl and a moving internal cone with its axis running at an angle to the machine axis. The displacement of the cone at each stroke is at a speed that permits pieces of rock to fall freely by gravity and be caught further down the rising head on its return stroke. In the case of a machine with a suspended head, short stroke and lower speed, the rocks will slide down the crushing opening using the same principle as the gyratory crusher. Throughput capacities vary depending on the range of the feed size and the setting of the outlet. They are most suited as a secondary crusher. However as a tertiary crusher with a shallow angled cone the crusher is sensitive to the moisture content of the feed material.

Adjustment of the outlet setting is either by wedge or the fixed crusher member rotated on a threaded ring. The latter method has been refined by the use of hydraulic controls so that settings may be altered without stopping the feed to the crusher. Further advances in computerized automation has led to a more accurate forecast of product size and power consumption. At the lower end of the crushing chamber the two faces of the ‘liners’ are shaped so as to be nearly parallel to each other. The effect of the parallel section of the liners is to ensure that the larger rocks have at least one dimension equal to, or less than, the setting and that all product will be less than twice this dimension. This setting is referred to as the ‘close side setting’. Reduction ratios of cone crushers are in the range of (6-8:1) if used as a secondary crusher and (2-3:1) if used as a tertiary crusher. Both crushing members are subjected to heavy abrasive action and must be fitted with substantial liners, usually made of manganese steel. As these types of crushers achieve the best results if the whole crushing cavity is utilized then they should be choke fed. A wide angle between the crushing liners will increase the reduction ratio and the capacity. A narrow angle has the opposite effect. A protection method installed on many cone crushers is a series of springs (fig-3.10) or hydraulic rams which allow the fixed cone jacket to rise up in the event of uncrushable material entering the chamber.

Tagged: Cone Crushers in IraqStone Crushing Plant IraqCrushing Machine for Sand Iraq

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)