Conveyors

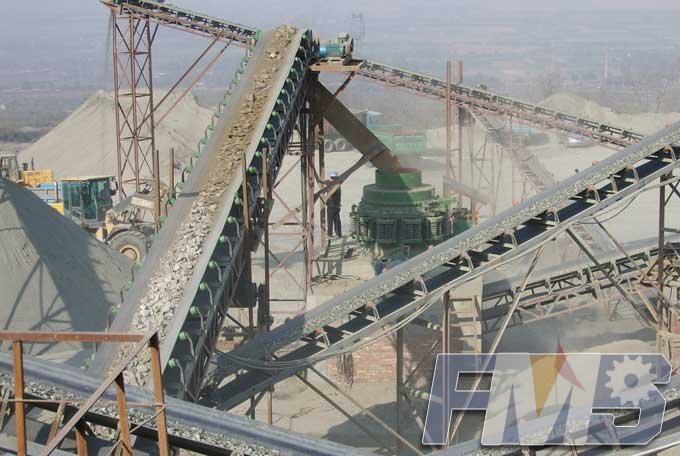

Conveyors as a means of moving material within crushing plants are preferred and common because they provide an even and continuous flow. Their mechanical efficiency is high as relatively little dead weight (ie. the conveyor itself) must be moved with the load. Further, frictional resistance is low (due to the numerous bearing supported rollers) and power consuming starts and stops are relatively rare.

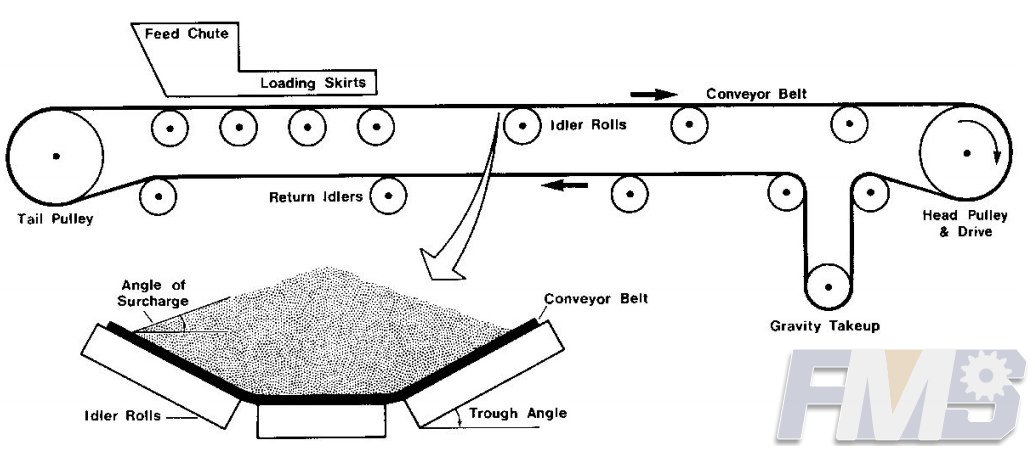

Basically, a conveyor is an endless moving flat belt for transporting dry materials. The belt extends between a head pulley, and a tail or return pulley. It is supported by idler rollers, which are, in turn, supported by a frame. The drive pulley is often located at the head end or at an intermediate point along the return run. Tension in the belt is provided by either a "take up" or "gravity" pulley, located just behind the drive pulley, or an adjustable tail pulley (more common on smaller length conveyors).

Belts, which move loose material, are usually run through a trough in the upper belt, which centres the load to reduce spill off the sides. Short conveyors, such as the feed conveyors can carry larger loads by using a flat surface with fixed side skirts to reduce material spillage.

Dust control (a common issue associated with conveyors) from conveyors is controlled as much as possible with the incorporation of some or all of the following;

- Two-stage loading skirts (usually steel internal with rubber or polyurethane external skirt)

- Dust extraction system operating from the loading skirt area

- Belt-scrapers adjacent the head pulley

- Chute design minimising impact velocity of ore onto the belt

- Water sprays & Belts covers

Tagged: Conveyors

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)