High-Pressure Grinding Rolls

High-pressure grinding rolls (HPGRs) are increasingly becoming a part of the hard-rock processing picture through their energy efficiency, the ability to induce microcracks and preferential liberation, coupled with high throughput and high reduction ratio. Given that the machine is still not regarded by many as an off-the-shelf piece of process equipment, there is work required to define guidelines for its use and to provide engineers with tools they can use. High-pressure grinding rolls (HPGRs) have struggled for acceptance into the hard-rock mining sector. Many of the issues that restricted their widespread use have now been conquered, but it is still regarded as an “immature” technology.

First, there are very few actual, or operating, applications in hard-rock duties. The only hard-rock applications that have been in existence for any length of time are restricted to the diamond and iron ore (pellet-feed) sectors.

Another consideration is that the HPGR is a very rare breed of machine, in that its development stemmed from fundamental research. Given the types and focus of early publications, much was made of the nature of the interparticle breakage at the heart of the technology. Obviously, given the ground-breaking nature of the invention, this focus was fully justified, but it led—unfairly—to the HPGR being regarded as an academic device searching for an industry application. The language used about the HPGR, and unfamiliar terms such as “m-dot” (denoting specific throughput), further led to an air of mystique around the HPGR. Was it a crusher or a mill? Its place in the world was unclear.

Another element restricting the rate of application was the lack of process models. Simulation is a large part of the flowsheet design exercise and this inevitably requires process models to exist for each piece of equipment. In the case of the HPGR, much of the effort was placed in scale-up procedures. Several organisations did produce process models of HPGRs, but they have been fragmented in their acceptance. Currently, the most complete model approach is that reported by Daniel and Morrell (2004), who have developed an approach from the earlier model of Tondo (1997). It is interesting to note that the Tondo model came out of the first major process study of HPGRs, namely the AMIRA P428 that was completed in 1997.

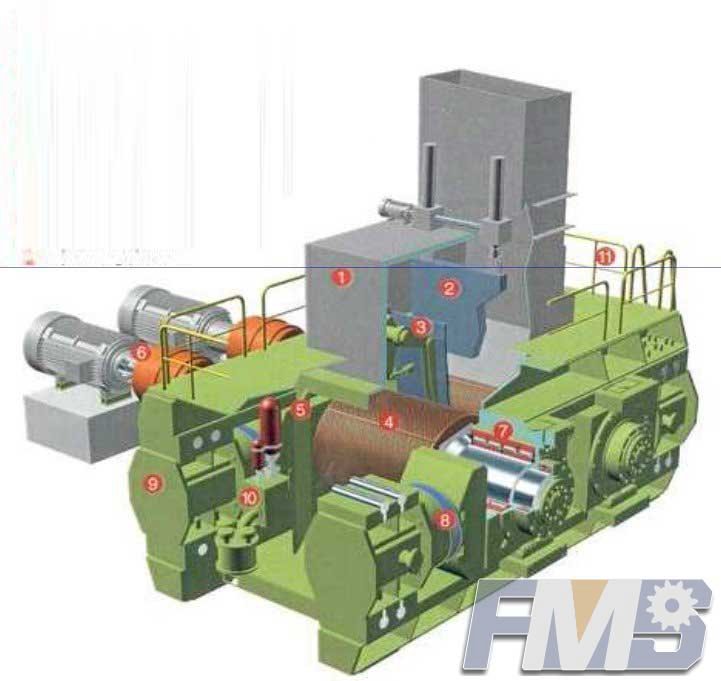

We offer High-Pressure Grinding Rolls and its Mature alternative products, If you are interested, please contact us.

Tagged: HPGR CrusherHigh Pressure Grinding MachineRoll Grinding Machine

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)