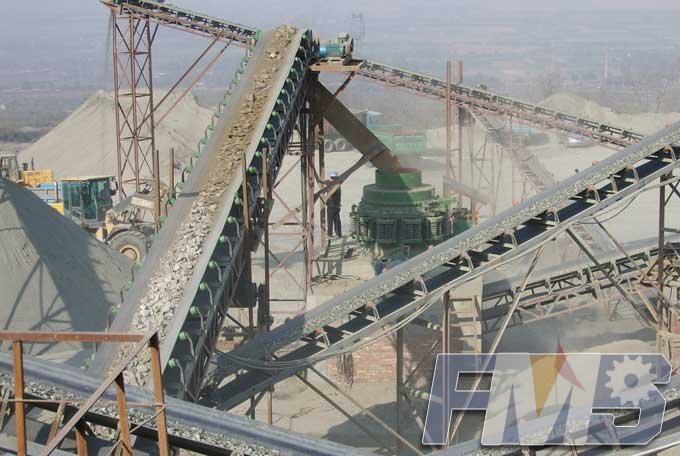

Fine Cone Crusher 300 TPH for Sale,Tertiary Crusher 300 TPH for Sale

The Cone crusher HPC315-F is our new stone crusher which capacity is reached 300 tons per hour and the minimum discharge size is 9 mm. This type of crusher, very commonly used as a tertiary crusher. They consist of an external fixed bowl and a moving internal cone with its axis running at an angle to the machine axis. The displacement of the cone at each stroke is at a speed that permits pieces of rock to fall freely by gravity and be caught further down the rising head on its return stroke. In the case of a machine with a suspended head, short stroke and lower speed, the rocks will slide down the crushing opening using the same principle as the gyratory crusher.

Adjustment of the outlet setting is either by wedge or the fixed crusher member rotated on a threaded ring. The latter method has been refined by the use of hydraulic controls so that settings my be altered without stopping the feed to the crusher. Furtheradvances in computerized automation has led to a more accurate forecast of product size and power consumption.

At the lower end of the crushing chamber the two faces of the ‘liners’ are shaped so as to be nearly parallel to each other. Figure 6 sketches the reduction principle. The effect of the parallel section of the liners is to ensure that the larger rocks haveat least one dimension equal to, or less than, the setting and that all product will be less than twice this dimension.

Both crushing members are subjected to heavy abrasive action and must be fitted with substantial liners, usually made of manganese steel. As these types of crushers achieve the best results if the whole crushing cavity is utilized then they should be chokefed. There are a number of different liners profiles available to suit different material characteristics and to select the best it is advisable to consult the supplier. A wide angle between the crushing liners will increase the reduction ratio and the capacity. A narrow angle has the opposite effect.

A protection method installed on many cone crushers is a series of springs or hydraulic rams which allow the fixed cone jacket to rise up in the event of uncrushable material entering the chamber. The simple operation and low level of maintenance required make for very economical use.

PRINTGET PRICEPrevious: Cement Crusher,Stone Crushing Machine for Cement Industry for Sale

Next: Excellent Double Roll Crusher Suppliers in China - Formats Construction Machinery

Tags: Stone Crusher 300 TPHFine Cone CrusherFine Tertiary Crushe

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)