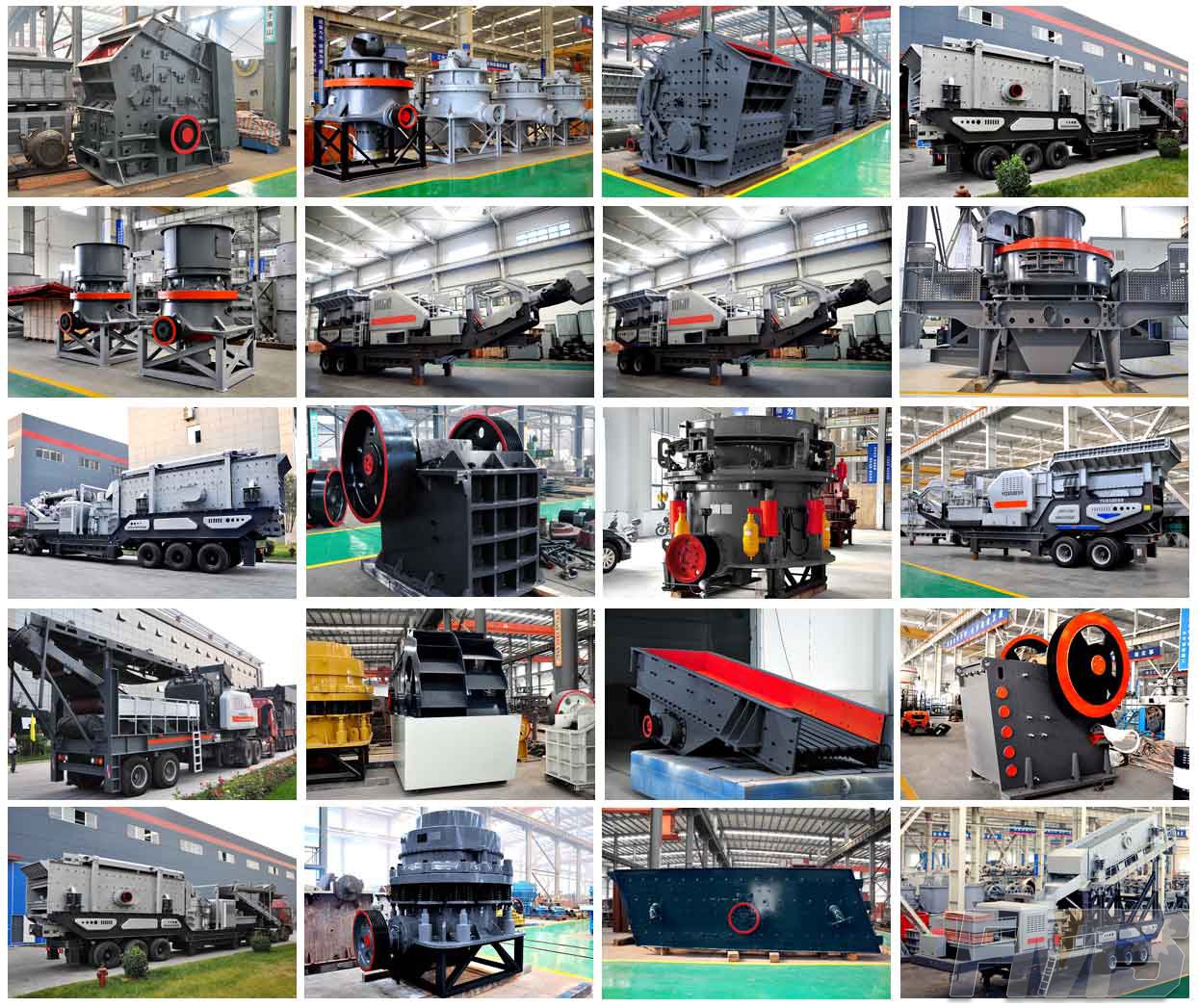

Cement Crusher,Stone Crushing Machine for Cement Industry for Sale

In general the total number of crushing stages in a comminution plant is determined by the overall reduction ratio required. In the cement industry the abrasiveness of the rock to be crushed is the primary determining factor of the number of reduction stages required. The plant feed originating from a quarry usually contains large rocks and boulders. The size of the first or primary crusher is usually specified by the total capacity required or maximum lump size of the feed. For hard abrasive rocks, such asDolerite, a compression type jaw or gyratory crusher is used for the primary crushing duty. Product size of this type is normally about 80 % passing 1000 mm to 250 mm. Normally feed to a gyratory is not pre-screened but may be necessary when using a jaw crusher to increase throughput. For softer rocks, such as limestone, an impact crusher will give the best results. They are designed for the crushing of non or low abrasive materials and have a high throughput and reduction ratio with a product containing a large percentage of fines. The power consumption of these machines is lower per ton throughput than for an equivalent size jaw or gyratory crusher. Because of their mechanical strength they are also suitable for the crushing of hard materials, but at a very much higher cost than for an equivalent compression crusher. Figure 1 illustrates the various common types of crushers. Reduction ratios vary between 3 to 1 and 7 to 1 for compression crushers and up to 50 to 1 for impact crushers. To obtain the maximum reduction ratios from any crusher is not the most economic way of crushing a material as it results in hang-ups and increased power consumption which leads to excessive costs.

Crushing machines were invented in the early 19th century. It was in 1858 that E.W. Blake invented the jaw crusher using the mechanical principal of the toggle linkage. For primary crushing of hard abrasive rocks Jaw crusher is still the best machine. Secondary crushing, at the turn of the century, was still in its infancy and need for a finer product was achieved by the use of a small gyratory after primary crushing by a large jaw or gyratory crusher. The earliest attempt to adapt the gyratory as a secondary crusher was the ‘short head’. This was a reduction of the size of the crushing head in a standard machine. In the 1920’s short head gyratory crushers designed specifically for secondary crushing were introduced.

PRINTGET PRICEPrevious: Single Roller Hammer Crusher for sale

Next: Fine Cone Crusher 300 TPH for Sale,Tertiary Crusher 300 TPH for Sale

Tags: Stone Crushing MachineCement Crushing PlantCement Crusher

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)