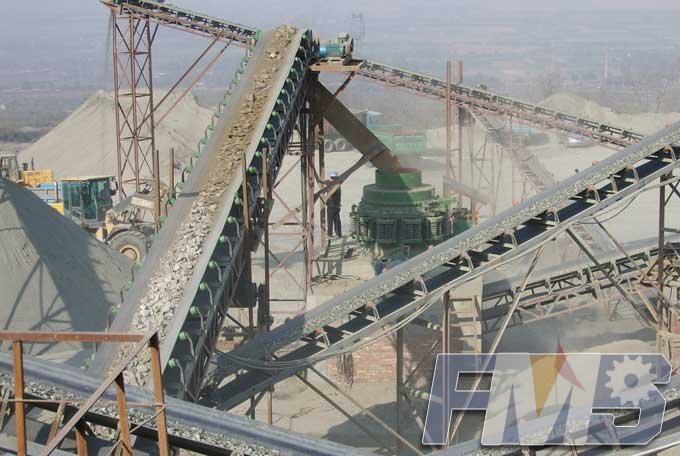

Formats, well-known producer of limestone and other rock processing equipment

Crushed rock is one of the most accessible natural resources and a major basic raw material. It is used in construction, agriculture, and other industries using complex chemical and metallurgical processes. Despite the low value of its basic products, the crushed rock industry is a major contributor to and an indicator of the economic well being of the nation.

About three-quarters of the crushed stone production is limestone and dolomite, followed by, in descending order of tonnage: granite, traprock, sandstone and quartzite, miscellaneous stone, marble, slate, calcareous marl, shell, volcanic cinder and scoria.

Limestone, one of the largest produced crushed rock, is a sedimentary rock composed mostly of the mineral calcite and comprising about 15 percent of the earth's sedimentary crust. This mineral is a basic building block of the construction industry and the chief material from which aggregate, cement, lime, and building stone are made. For the purposes of this report, limestone will be used as a sample for crushed rock.

One product of limestone mining is lime. A wide range of industries use lime for a myriad of uses. It is used in many of the products and materials Americans use every day, including paper, steel, sugar, plastics, paint, and many more. The largest single use of lime is in steel manufacturing, for which it serves as a flux for removing impurities (silica, phosphorus and sulfur) in refining steel. It is used both in traditional basic oxygen furnaces (BOF) and the newer electric arc furnaces, as well as in secondary refining. Lime for use in the steel industry--both high calcium and dolomitic--must meet exacting specifications for physical and chemical properties. Without this high-quality lime, U.S. steel production would be crippled. Lime is also essential to producing metals other than steel. It is used to beneficiate copper ore, to make alumina and magnesia for use in aluminum and magnesium manufacture, to extract uranium, and to recover gold and silver.The second leading use of lime is for environmental applications, involving air, drinking water, wastewater, and solid wastes. Industrial, utility, and mining operations rely on lime to comply with a host of environmental regulations. Lime is used to treat industrial and mining wastewater, in which it adjusts the pH of acidic waste, removes phosphorus and nitrogen, and promotes clarification. A growing use of lime is in the treatment of stack gases from industrial facilities, power plants, medical waste incinerators, and hazardous waste incinerators. Lime absorbs and neutralizes sulfur oxides from these gases, helping to prevent acid rain, and also reduces emissions of hazardous air pollutants, including mercury. Lime is especially vital to municipalities in meeting their environmental and public health responsibilities at a reasonable cost. First, lime is widely used for potable water softening and to remove impurities (such as lead) from drinking water. Second, it is a cost-effective method for treating sewage sludge. Third, stack gases from municipal incinerators are treated with lime to remove sulfur dioxide, hydrogen chloride and other contaminants. These applications of lime are important in maintaining a clean environment.

In construction, lime's traditional use is in mortar and plaster, because of its superior plasticity, workability, and other qualities. Lime's dominant construction use today is in soil stabilization for roads, airfields, building foundations, and earth dams, where it upgrades low quality soils into usable base and subbase materials. It is also used as an additive in asphalt to improve the cohesion of the asphalt, reduce "stripping," that retards the aging process. Dolomitic lime is also used in the production of masonry mortar and stucco, and high calcium lime is used in the production of aerated autoclaved concrete.

In addition to the uses described above, lime is essential to many other industries. For example, the chemical industry uses lime to manufacture sodium alkalies, calcium carbide, calcium hypochlorite, citric acid, petrochemicals, phenolates, stearates, naphthenates, nitrates, caseinates, calcium phosphates, propylene glycol, glycerin, and many others. These chemicals, in turn, go into virtually every product made in America. An important and growing use for lime is in the production of precipitated calcium carbonate (PCC), which is used in the production of paper, paint, ink, plastic, and rubber. The paper industry uses lime as a causticizing agent and for bleaching and, increasingly, for producing PCC for use in the paper manufacturing process.

PRINTGET PRICEPrevious: Mobile Cone Crusher On Chassis for Sale

Next: Ball Mill will be Replaced by other Grinding Mills

Tags: Rock Processing Equipmentlimestone crusher and grinder

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)