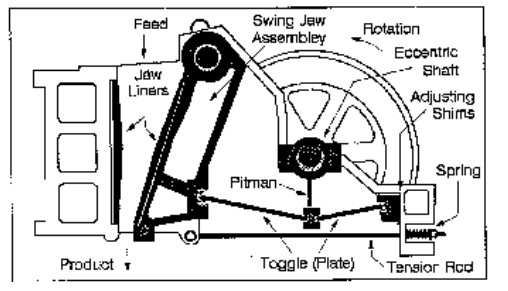

Double Toggle Jaw Crusher Working Principle

The moving jaw is freely suspended from a shaft at its top edge and the jaw movement is transmitted through toggles near the lower edge. Maximum crushing force is applied at the inlet to the crushing chamber where the largest particles are found.

The moving jaw is suspended from a cross shaft at its upper end, this shaft in turn being supported at each end in bearings at the top of the two sides of the crusher frame. The actuating mechanism consists of the eccentric shaft, supported in bearings, the pitman and the pair of toggles. The motion of the eccentric shaft is transmitted through the pitman to the inner ends of the toggle pair. The setting of the toggle plates alternatively increases and decreases the effective length of the toggles, imparting the horizontal crushing motion to the jaw. The motion is greatest at the discharge opening.

In both machines the toggles are clamped in position by spring loaded bolts attached to the moving jaw, taking up the motion of the jaw. The crushing action is intermittent allowing the rock to fall further down the crushing chamber before being crushed again. This action can cause choking if overfeeding takes place and it is best to control the feed to this type of crusher.

The single toggle crusher will not take such hard rock as the double toggle unit. With a rock of medium hardness the single unit will have a larger throughput, due to the travel of the jaw. Where the rock to be crushed is highly laminated the jaw crusher tends to produce slabs. This can make handling of feed material to secondary crushers difficult.

Tagged: double toggle jaw crusherJaw Crusher Working Principle

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)