SAG Mill Pebble Crushing

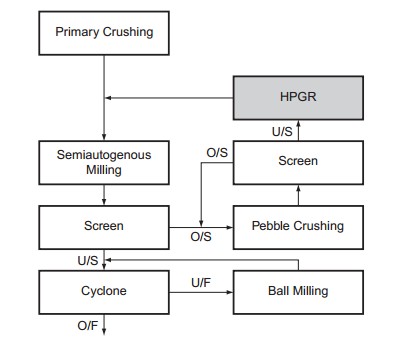

Further size reduction of the pebble fraction in an SABC (semiautogenous-ball-crusher) circuit can be achieved by passing the pebble crusher product through an HPGR, thus increasing circuit capacity. Alternatively, the conventional cone crusher may be replaced entirely by an HPGR, provided the pebble top size is small enough.

In a variation, the pebble crusher and HPGR can be operated in closed circuit with the screen undersize delivered to the ball milling circuit. This circuit can be used to open-circuit the SAG mill when this is the circuit bottleneck.

These circuits have the disadvantage of exposure of the HPGR to tramp steel in the SAG mill discharge. Also, the use of HPGR in the pebble-crushing circuit can usually be justified only when pebble arisings are a relatively large proportion of SAG mill new feed.

Tagged: SAG MillPebble Crushing

Get Detail Information:

(If you do not want to contact to our online customer service, please fill out the following form, Our client manager will contact you later. We will strictly protect your privacy.)